User

Manual

GFK-2308W

May 2021

PACSystems™ RX3i Hot Standby

CPU Redundancy

Warnings and Caution Notes as Used in this Publication

WARNING

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or may be

associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a Warning

notice is used.

CAUTION

Caution notices are used where equipment might be damaged if care is not taken.

Note: Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

These instructions do not purport to cover all details or variations in equipment, nor to provide for

every possible contingency to be met during installation, operation, and maintenance. The

information is supplied for informational purposes only, and Emerson makes no warranty as to the

accuracy of the information included herein. Changes, modifications, and/or improvements to

equipment and specifications are made periodically and these changes may or may not be reflected

herein. It is understood that Emerson may make changes, modifications, or improvements to the

equipment referenced herein or to the document itself at any time. This document is intended for

trained personnel familiar with the Emerson products referenced herein.

Emerson may have patents or pending patent applications covering subject matter in this document.

The furnishing of this document does not provide any license whatsoever to any of these patents.

Emerson provides the following document and the information included therein as-is and without

warranty of any kind, expressed or implied, including but not limited to any implied statutory

warranty of merchantability or fitness for particular purpose.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Contents

GFK-2308W May 2021

Contents iii

Contents

Section 1: Introduction ..................................................... 1

1.1 Hot Standby CPU Redundancy ..................................................................... 1

1.2 PACSystems HSB Redundancy Feature Summary ......................................... 4

1.3 Online Programming ................................................................................... 6

1.4 Online Repair and System Upgrade .............................................................. 6

1.5 Definitions................................................................................................... 6

1.6 PROFINET Definitions .................................................................................. 8

1.7 Revisions in this Manual ............................................................................. 11

1.8 Documentation ......................................................................................... 12

1.8.1 RX3i Manuals .................................................................................. 12

1.8.2 VersaMax Manuals .......................................................................... 12

Section 2: RX3i Hot Standby Redundancy Quick Start with

PROFINET I/O ...................................................................... 13

Section 3: RX3i Hot Standby Redundancy Quick Start with

Ethernet I/O 21

Section 4: System Configuration ..................................... 28

4.1 Components of a Hot Standby Redundancy System .................................. 28

4.1.1 Core Systems .................................................................................. 28

4.1.2 Redundant CPU Modules ................................................................. 29

4.1.3 Redundancy Memory Xchange Modules .......................................... 31

4.1.4 Redundant I/O Systems ................................................................... 32

4.1.5 Local I/O .......................................................................................... 33

4.2 CPU Redundancy Using PROFINET I/O ........................................................ 33

4.2.1 Configuration Considerations .......................................................... 33

4.2.2 Configuration Overview .................................................................. 34

4.2.3 PROFINET Network Architectures .................................................... 35

4.3 CPU Redundancy Using Ethernet NIU Remote I/O ...................................... 37

4.3.1 Dual Controller, Single LAN Systems ................................................ 37

4.3.2 Dual Controller, Dual LAN Systems .................................................. 39

4.4 Genius Hot Standby Operation .................................................................. 40

4.4.1 Genius Output Control .................................................................... 40

4.4.2 Basic CPU Redundancy Using Genius I/O ......................................... 40

Section 5: Configuration Requirements .......................... 45

5.1 Overview ................................................................................................... 45

5.1.1 Setting up a CPE400 or CPL410 for Redundancy .............................. 46

5.1.2 Setting up a CPE330 for Redundancy ............................................... 51

5.2 PROFINET I/O Configuration ...................................................................... 55

5.2.1 Requirements ................................................................................. 55

5.2.2 Restrictions ..................................................................................... 55

5.2.3 Generating the Hardware Configuration ......................................... 56

5.2.4 Downloading PROFINET I/O Configuration to the HSB CPU

Redundancy System ........................................................................ 62

5.2.5 Adding or Modifying a PROFINET I/O Device without Stopping the

Process ........................................................................................... 64

5.3 Using the Redundancy Wizards ................................................................. 73

5.3.1 Synchronizing the Hardware Configurations ................................... 74

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Contents

GFK-2308W May 2021

Introduction iv

5.4 Hardware Configuration Parameters ......................................................... 75

5.4.1 CPU Parameters .............................................................................. 75

5.4.2 Scan Parameters ............................................................................. 75

5.4.3 Redundancy Memory Xchange Module Parameters ......................... 82

5.4.4 Ethernet Interface Parameters ......................................................... 82

5.4.5 Rack Module Configuration Parameters .......................................... 84

5.4.6 Genius Bus Configuration ................................................................ 85

5.5 Adding Individual Variables to the Transfer Lists ........................................ 86

5.5.1 Mapped Variables ........................................................................... 87

5.5.2 Arrays ............................................................................................. 87

5.5.3 Instance Data Structure Variables .................................................... 87

5.5.4 Using the Variable Transfer List Report ............................................ 87

5.6 Storing (Downloading) Hardware Configuration ........................................ 89

5.7 Run Mode Store ......................................................................................... 90

5.7.1 Dual RMS with Simultaneous Activation in Redundant Systems ....... 90

5.7.2 Initial RMS Followed by Dual RMS .................................................... 91

5.7.3 RMS Operational Errors ................................................................... 92

5.7.4 Behavior of EGD in a Dual RMS ......................................................... 94

5.7.5 Hardware Configuration and Logic Coupling ................................... 94

Section 6: Operation ....................................................... 95

6.1 Power-up of a Redundant CPU ................................................................... 95

6.1.1 Synchronizing the Time of Day Clocks ............................................. 96

6.1.2 Validity of PROFINET I/O at Power-up .............................................. 97

6.2 Synchronizing Redundant CPUs ................................................................. 97

6.2.1 Dual Synchronization ...................................................................... 98

6.2.2 Resynchronization .......................................................................... 98

6.2.3 Operation when a Redundancy Link is Removed .............................. 98

6.3 %S References for CPU Redundancy ........................................................... 99

6.3.1 Redundancy Status Presented as OPC UA Variables ....................... 100

6.4 Scan Synchronization .............................................................................. 101

6.4.1 Synchronization of PROFINET I/O .................................................. 101

6.5 Fail Wait Time .......................................................................................... 102

6.6 Data Transfer ........................................................................................... 102

6.6.1 Synchronization and Data Transfer Process ................................... 102

6.6.2 Estimating Data Transfer Time ...................................................... 103

6.6.3 Programming a Data Transfer from Backup Unit to Active Unit

(SVC_REQs 27 & 28) ...................................................................... 107

6.6.4 Disabling Data Transfer Copy in Backup Unit (SVC_REQ 43) ........... 108

6.6.5 Validating the Backup Unit (SVC_REQ 43) ..................................... 111

6.7 Switching Control to the Backup Unit ...................................................... 111

6.7.1 PROFINET I/O Switchovers ............................................................. 112

6.7.2 Switching Times and Impact to Sweep Time .................................. 112

6.7.3 Commanding a Role Switch from the Application Program (SVC_REQ

26) ................................................................................................ 113

6.7.4 Implementing Preferred Master Using SVC_REQ 26....................... 114

6.8 STOP to RUN Mode Transition ................................................................. 114

6.8.1 Behavior with PROFINET I/O when No Healthy Redundancy Links are

Available ....................................................................................... 114

6.8.2 Validity of PROFINET I/O Immediately after a Configuration Download

116

6.9 RUN with Outputs Disabled Mode ........................................................... 116

6.10 RUN to STOP Mode Transition ................................................................. 117

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Contents

GFK-2308W May 2021

Introduction v

6.10.1 Behavior with PROFINET I/O when no Healthy Redundancy Links are

Available ....................................................................................... 117

6.11 Error Checking and Correction ................................................................. 118

6.12 Timer and PID Functions .......................................................................... 118

6.13 Timed Contacts ....................................................................................... 119

6.14 Multiple I/O Scan Sets .............................................................................. 119

6.15 Genius Bus Controller Switching .............................................................. 119

6.16 Redundant IP Addresses .......................................................................... 120

6.16.1 Validation and Activation of Redundant IP Addresses .................... 120

6.16.2 Monitoring and Deactivation of Redundant IP Address .................. 121

6.16.3 Operation of Redundant IP Address if both Redundancy Links Fail . 122

6.17 Ethernet Global Data in an HSB Redundancy System ................................ 123

6.17.1 Ethernet Global Data Production ................................................... 123

6.17.2 Ethernet Global Data Consumption ............................................... 125

Section 7: Faults ........................................................... 126

7.1 Fault Response ........................................................................................ 126

7.1.1 Faults for PROFINET I/O ................................................................. 127

7.2 Fault Actions ........................................................................................... 127

7.2.1 Configuration of Fault Actions ....................................................... 129

7.2.2 Configurable Fault Groups ............................................................. 130

7.2.3 Non-Configurable Fault Groups ..................................................... 131

7.2.4 Fatal Faults on Both Units in the Same Sweep ................................ 132

7.3 Controller Fault Table Messages for Redundancy ..................................... 132

7.3.1 Redundancy Fault Group (138) ...................................................... 132

7.3.2 Other Fault Groups ........................................................................ 136

7.4 Redundancy Link Failures ......................................................................... 137

7.4.1 Redundancy Memory Xchange Module Hardware Failure .............. 137

7.4.2 Redundancy Link Communications Failures ................................... 138

7.4.3 When the Last Redundancy Link Fails............................................. 138

7.4.4 CPE400/CPL410 Redundant Link Recovery .................................... 139

7.5 Online Repair and System Upgrade .......................................................... 139

7.5.1 Online Repair Recommendations .................................................. 140

7.5.2 Hot Swapping of Modules (RX3i Systems Only) ............................. 140

7.5.3 Hot Swapping Controllers (CRU320 to CPE330) ............................. 141

7.5.4 System CPU Upgrade .................................................................... 141

7.5.5 Online Repair of the Genius Bus ..................................................... 142

7.5.6 Repair of a Non-Synchronized Active Unit (NSAU) Split Control System

143

Appendix A RX3i Dual Genius Bus Overview ...................... 145

A 1.1 Features ........................................................................................ 145

A 1.2 Templates ..................................................................................... 145

A 1.3 Available Templates ...................................................................... 147

A 1.4 How to Choose a Template ........................................................... 147

Appendix B RX3i Dual Bus Genius Functionality ................. 148

Appendix C Switching Control to the Backup Unit When it has

Better PROFINET Connectivity than the Active Unit ........... 149

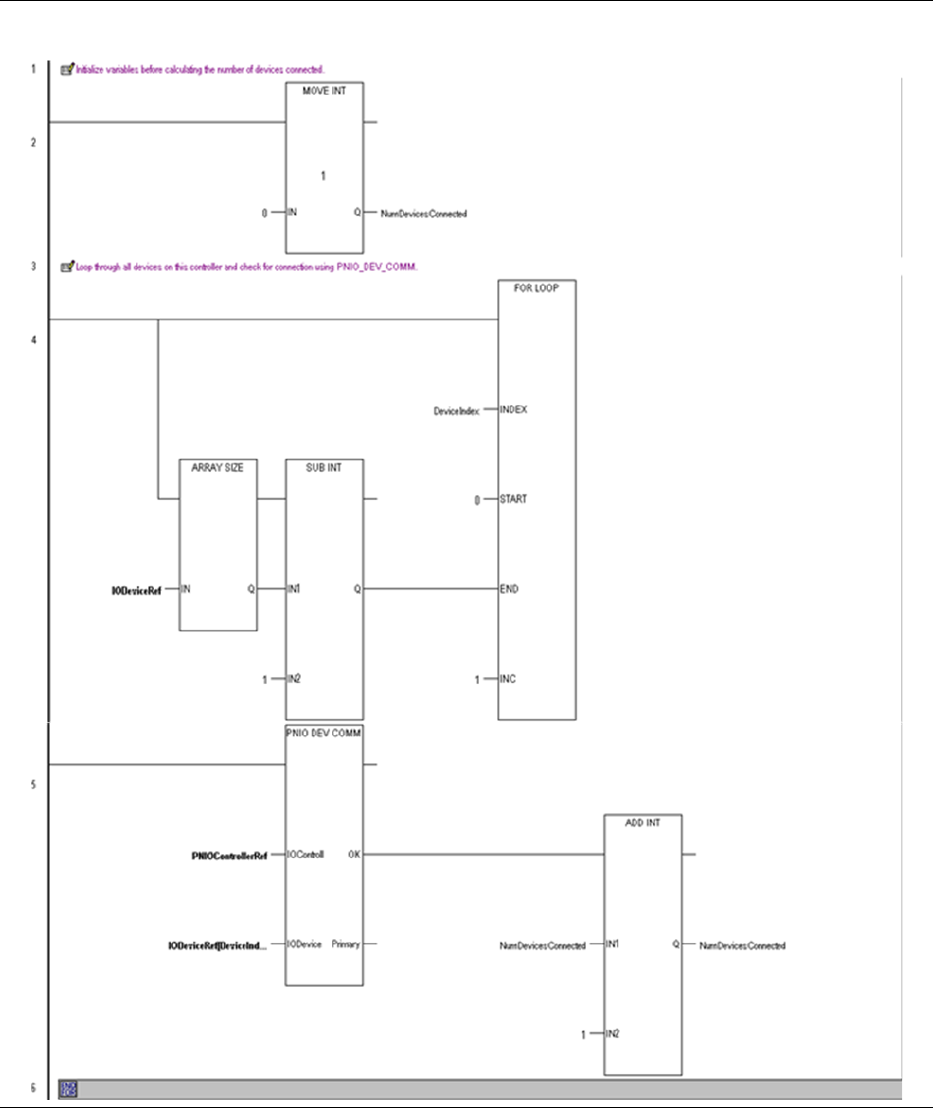

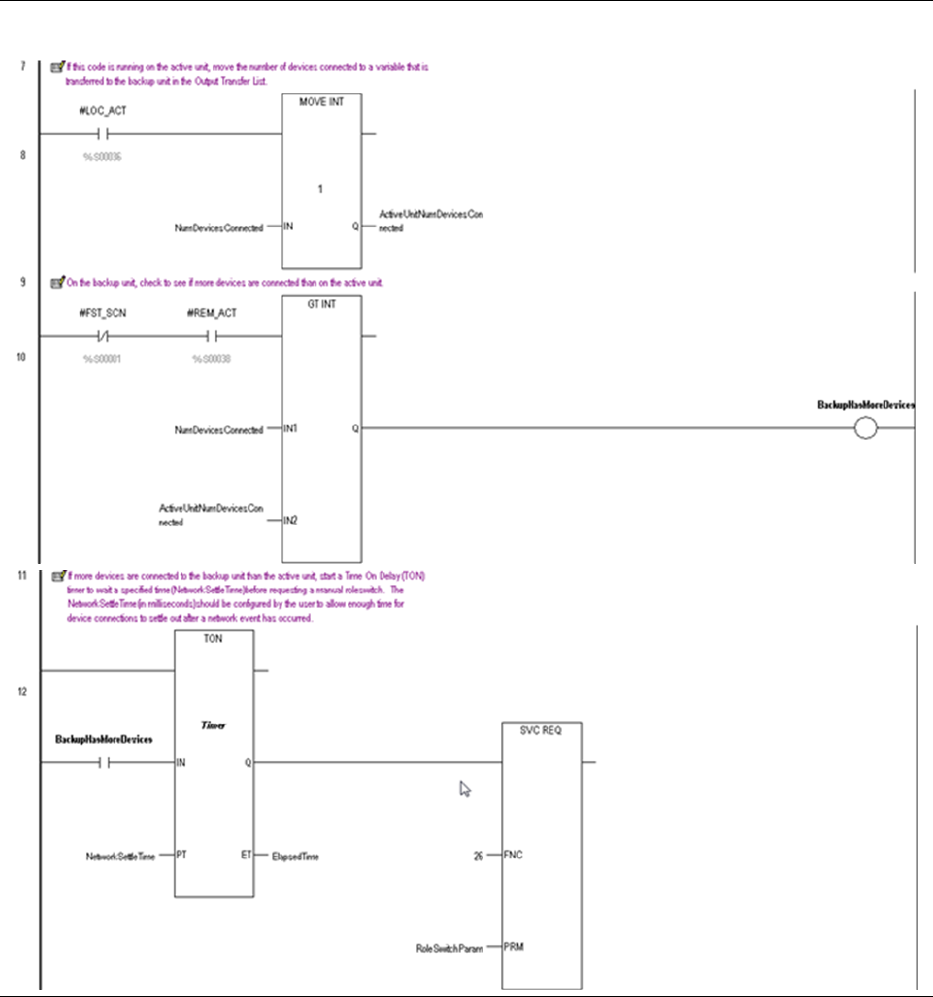

C 1.1 Overview ....................................................................................... 149

C 1.2 Application Examples .................................................................... 149

Appendix D Redundant I/O Wiring Details And Programming

Strategies 154

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Contents

GFK-2308W May 2021

Introduction vi

D 1.1 Introduction .................................................................................. 154

D 1.2 Redundant I/O Wiring Details ........................................................ 154

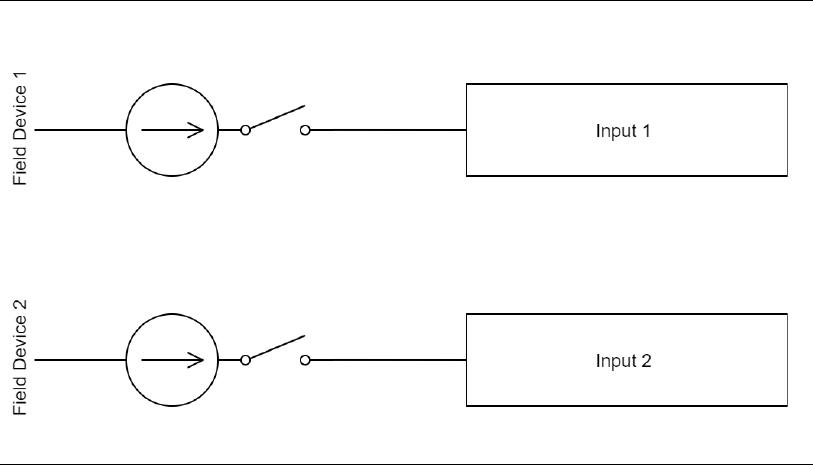

D 1.3 Dual Redundant Discrete Inputs With Dual Redundant Field Device

155

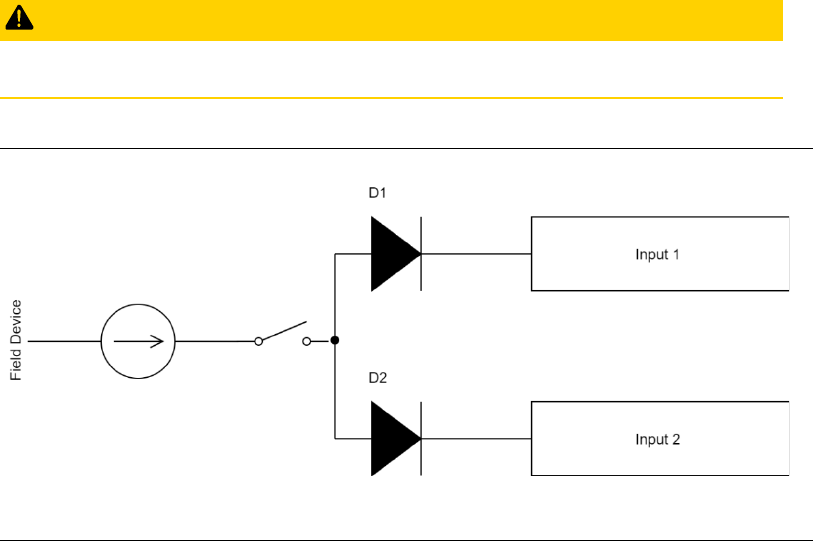

D 1.4 Dual Redundant Discrete Inputs With Single Field Device .............. 156

D 1.5 Dual Redundant Analogue Inputs With Dual Redundant Field Device

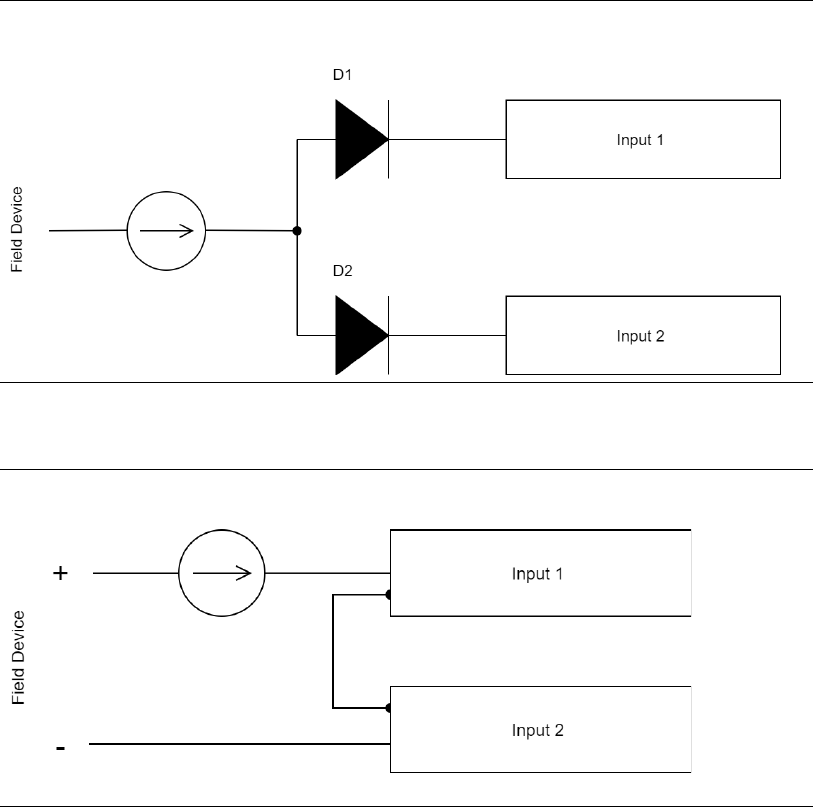

157

D 1.6 Dual Redundant Analogue Inputs With Single Field Device ............ 158

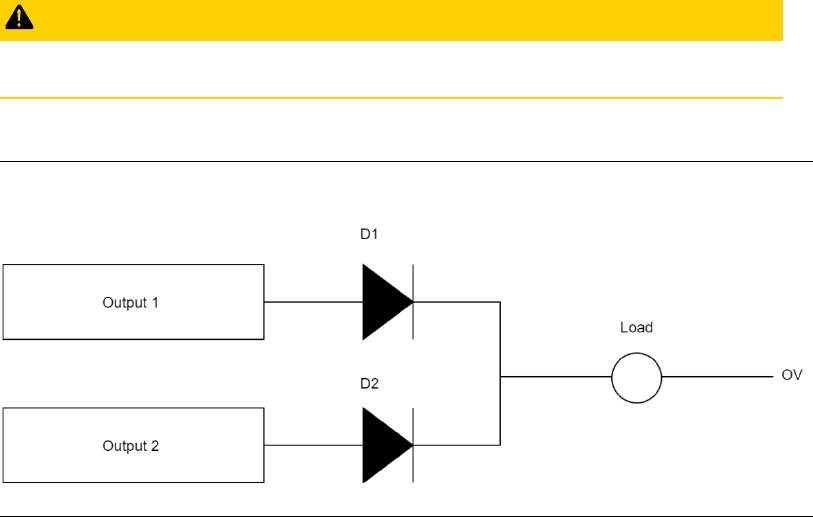

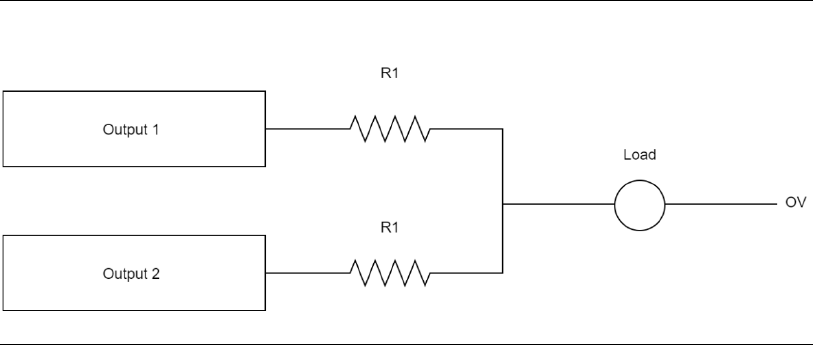

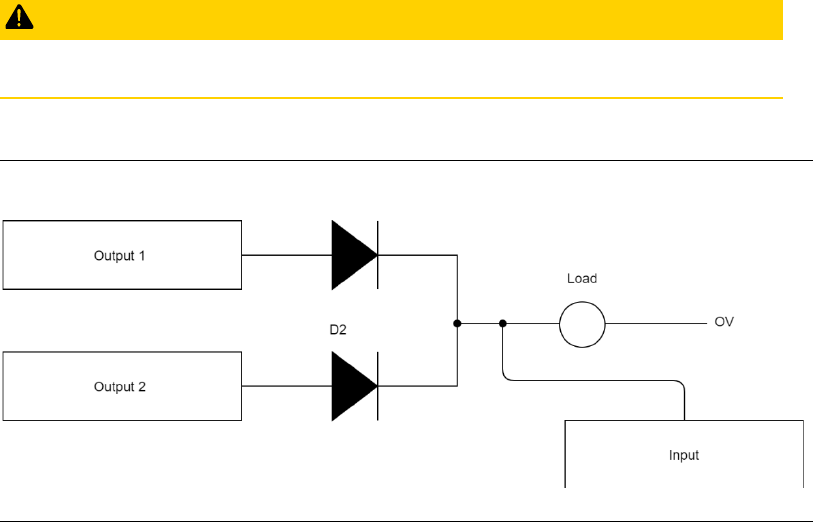

D 1.7 Dual Redundant Discrete Outputs with Single Field Device ............ 159

D 1.8 Dual Redundant Analogue Outputs With Single Field Device ......... 160

D 1.9 Dual Redundant Outputs With Single Field Device And Input Feedback

161

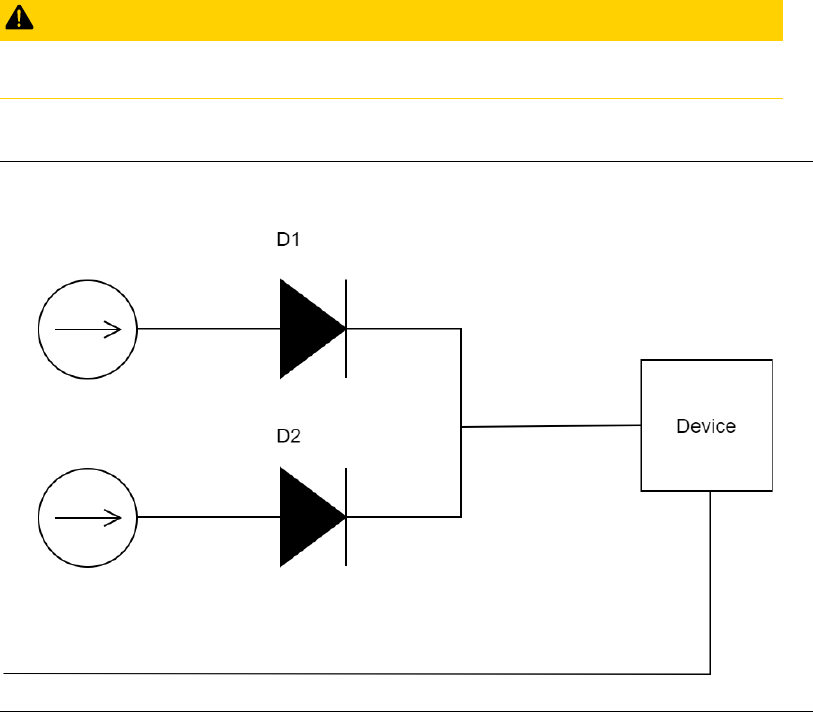

D 1.10Redundant Power Supply Wiring ................................................... 162

D 1.11Alternatives to Diodes ................................................................... 162

D 1.12Redundant I/O Programming Strategies ........................................ 163

D 1.13Dual Redundant Discrete Inputs .................................................... 163

D 1.14Dual Redundant Analogue Inputs .................................................. 164

D 1.15Dual Redundant Outputs ............................................................... 164

D 1.16Dual Redundant Outputs With Input Feedback .............................. 164

D 1.17Glossary ........................................................................................ 165

General Contact Information ................................................................... 166

Technical Support ................................................................................... 166

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 1

GFK-2308W May 2021

Introduction 1

Section 1: Introduction

This manual is a reference to the hardware components, configuration,

programming and operation of Hot Standby CPU redundancy for the PACSystems

RX3i. The information in this manual is intended to supplement the system

installation, programming, and configuration information contained in the manuals

listed under Related Documents.

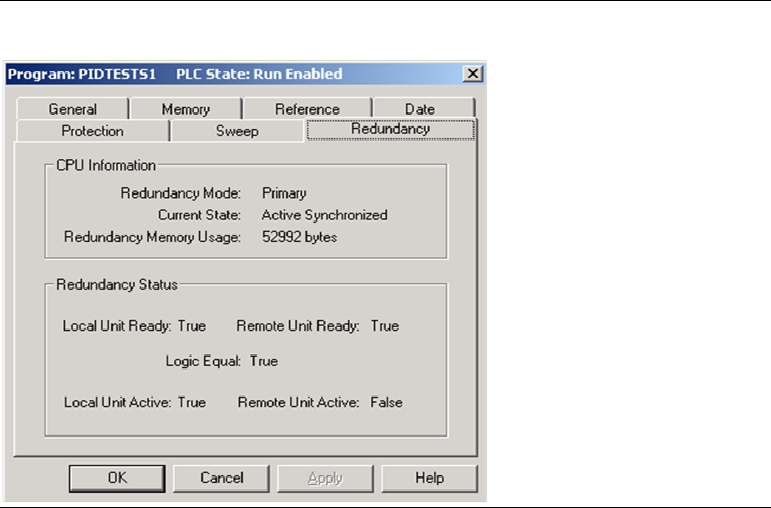

1.1 Hot Standby CPU Redundancy

Hot Standby CPU Redundancy allows a critical application or process to continue

operating should a failure occur in any single component. A Hot Standby system uses

two CPUs: an Active unit that actively controls the process, and a Backup unit that is

synchronized with the Active unit and can take over the process if it becomes

necessary. The two units are synchronized when both are in Run Mode: the Backup

unit will have received the latest status and synchronization information from the

Active unit via a redundancy link, and each is running its logic solution in parallel.

There are two distinctly different set-ups for Redundancy:

Traditional rack-mounted RX3i CPU systems (including CPE330), which require that

Redundancy Memory Xchange (RMX) modules be installed in each CPU rack. The

redundancy communication path is provided by a pair of RMX modules, one in the

rack of the Active (Primary) CPU, one in the rack of the Backup (Secondary) CPU. A

second pair of RMX modules may be used to create a redundant communication link.

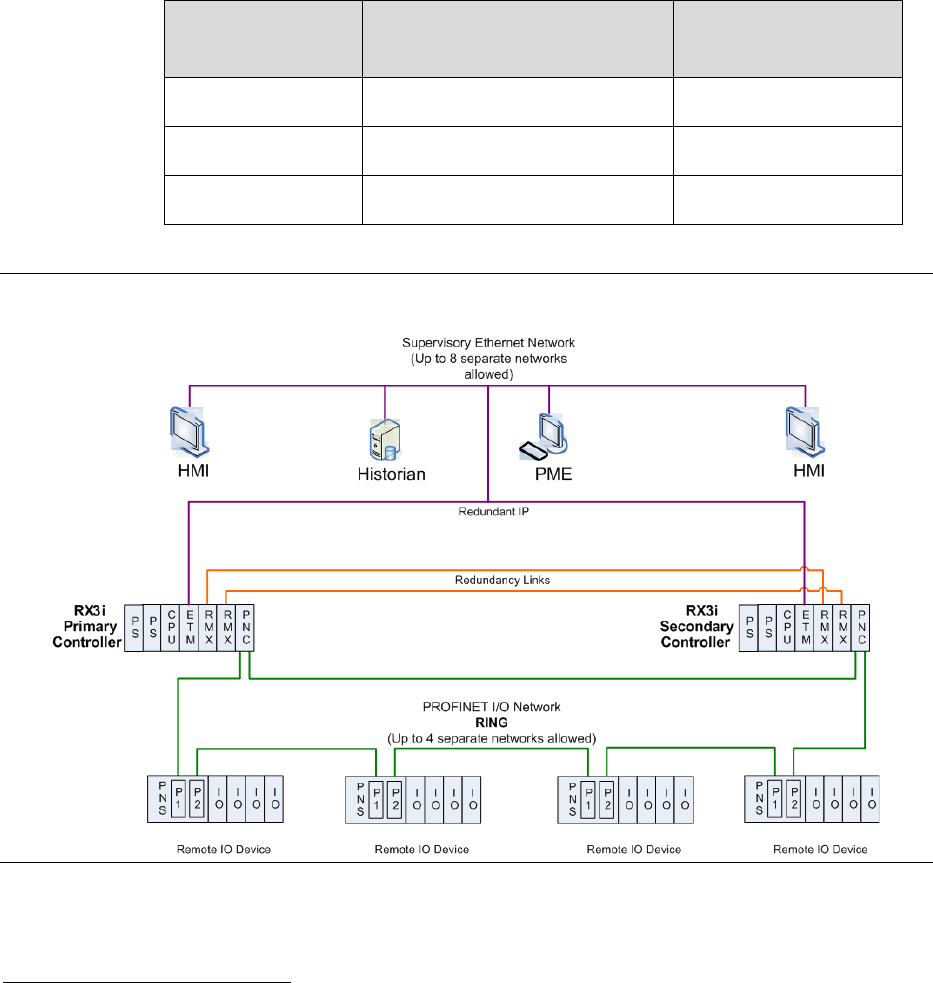

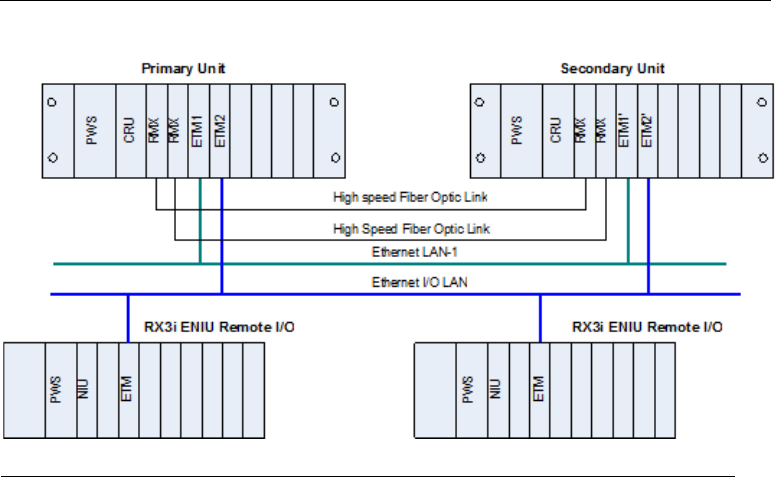

Refer to Figure 1 for a traditional system, and to Figure 2 for a CPE330 system.

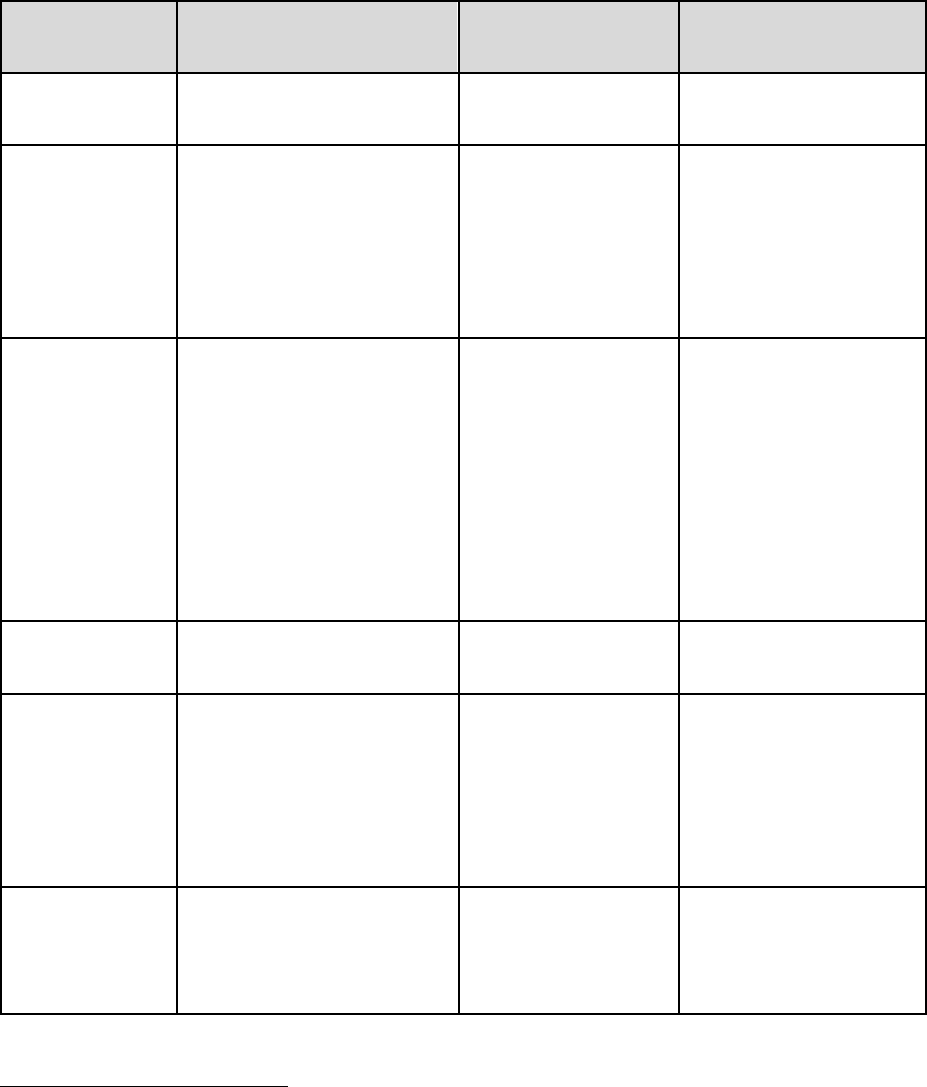

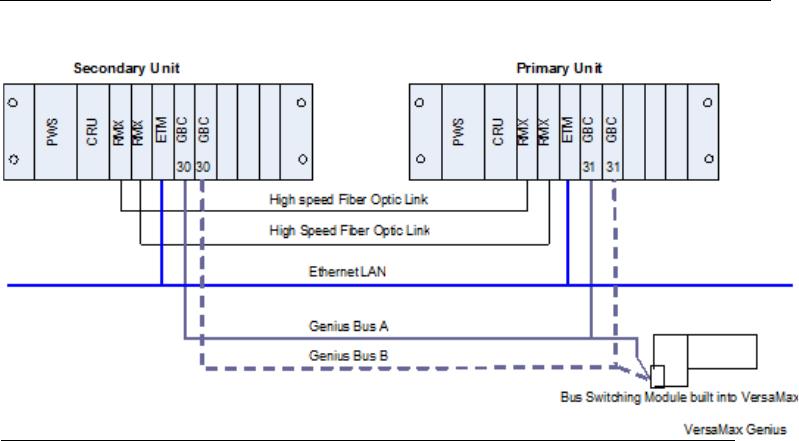

CPE400 and CPL410 do not use RMX modules. Rather, they use their own built-in

LAN3 ports to support the required redundancy communications links between

Primary and Secondary. LAN3 is a dedicated, secure, point-to-point Ethernet link

which does not support any additional equipment. Only a pair of CPE400 CPUs may

be interconnected on LAN3, as shown in Figure 3. Similarly, only a pair of CPL410

CPUs may be interconnected if using CPL410.

Note: In redundancy systems, we strongly recommend using a second

communications link, as shown in Figure 1 thru Figure 3. In Figure 1 and Figure 2, two

pairs of RMX modules configured as dual redundancy links are used. In Figure 3 each

CPU is connected to the other via both ports on LAN3. This practice eliminates the

possibility of a single point of failure that using only one communication link

presents.

Control automatically switches to the Backup unit when a failure is detected in the

Active unit. The user can initiate a switch of control by activating a toggle switch on

the RMX module or by activating a service request in the application program. When

a user-initiated switch of control occurs, the CPUs switch roles; the Active unit

becomes the Backup unit and the Backup unit becomes the Active unit.

The system runs synchronously with a transfer of all control data that defines

machine status and any internal data needed to keep the two CPUs operating in sync.

Critical control data plus all redundant outputs must be included in the output data

transfer. The transfer of data from the Active unit to the Backup unit occurs twice per

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 1

GFK-2308W May 2021

Introduction 2

sweep, once before the logic is solved and once after the logic is solved. These CPU-

to-CPU transfers are checked for data integrity.

The Primary and Secondary CPUs in a redundancy system must be in the same

Controller family. An RX3i Controller cannot function as a redundant pair. Similarly,

CPE400 must be paired with CPE400, CPL410 with CPL410, and CPE330 with

CPE330

1

.

The following versions of CPU firmware are required to support Redundancy:

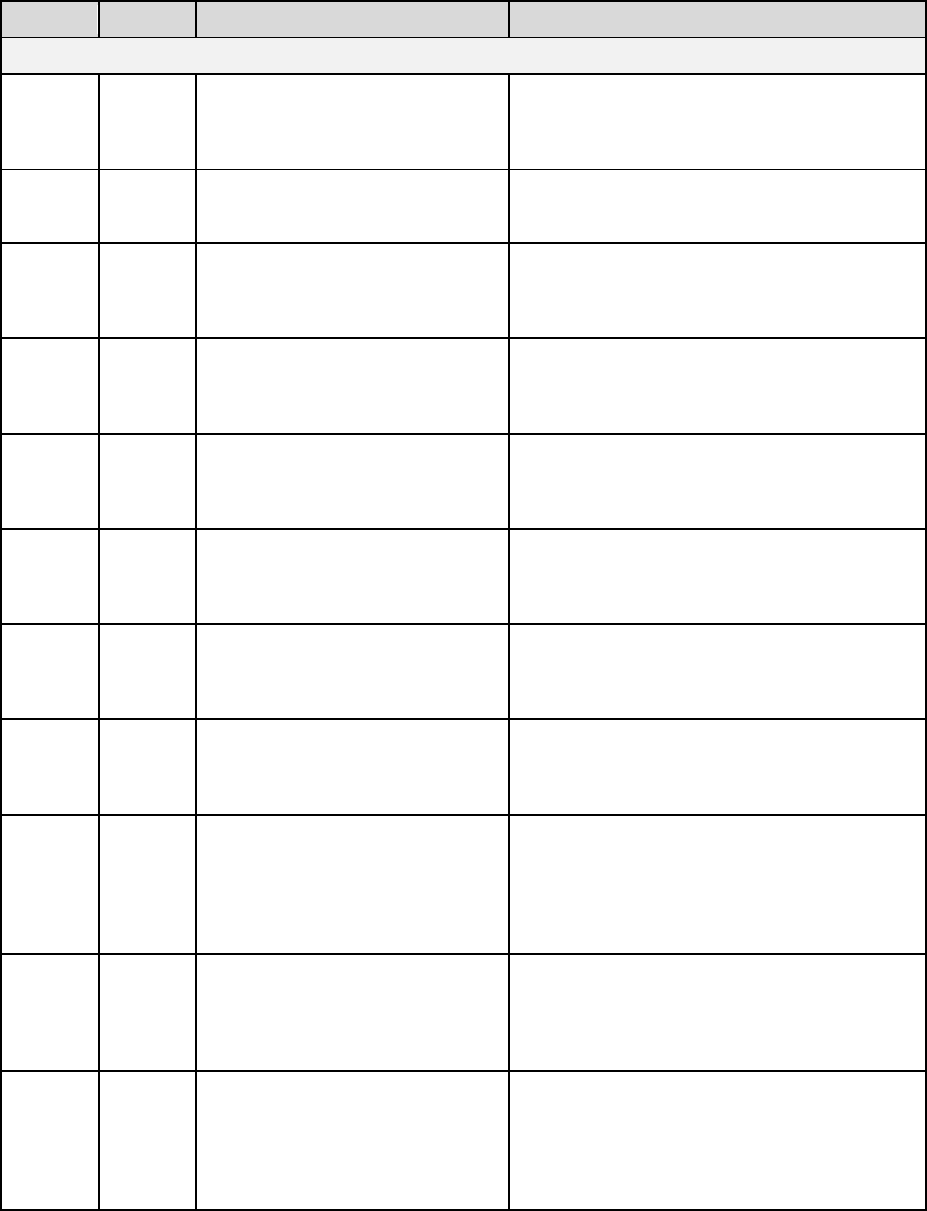

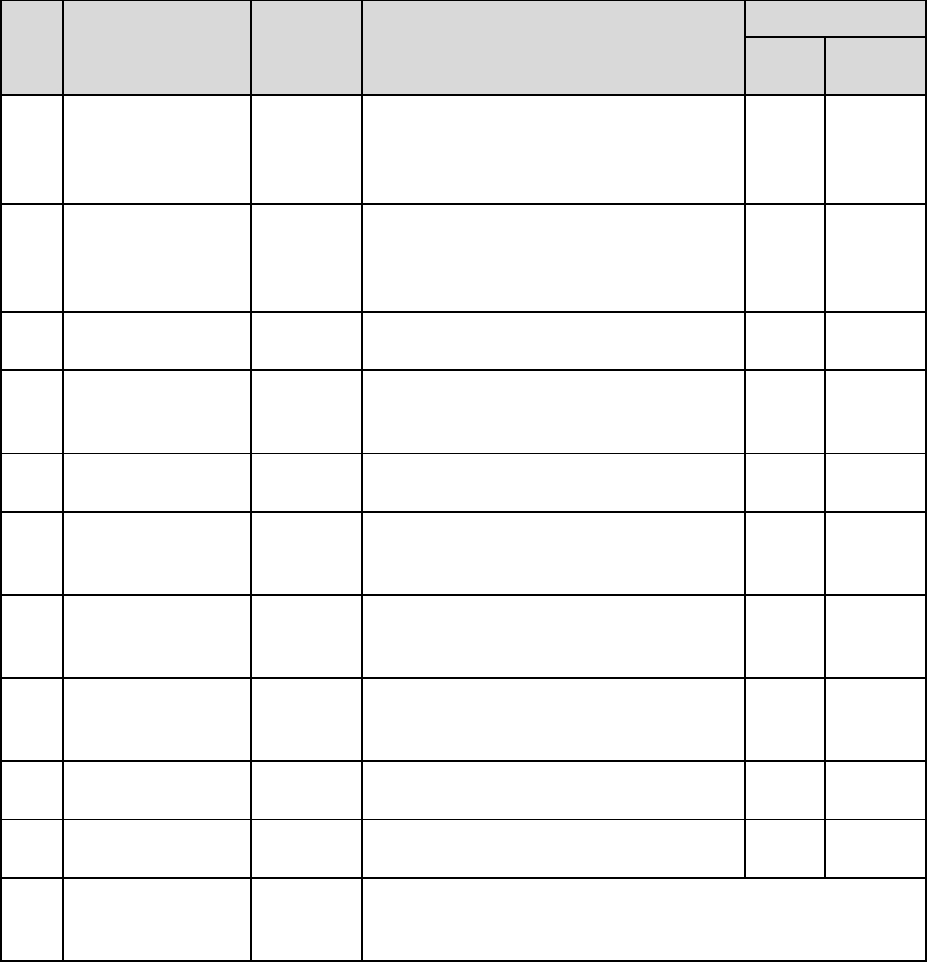

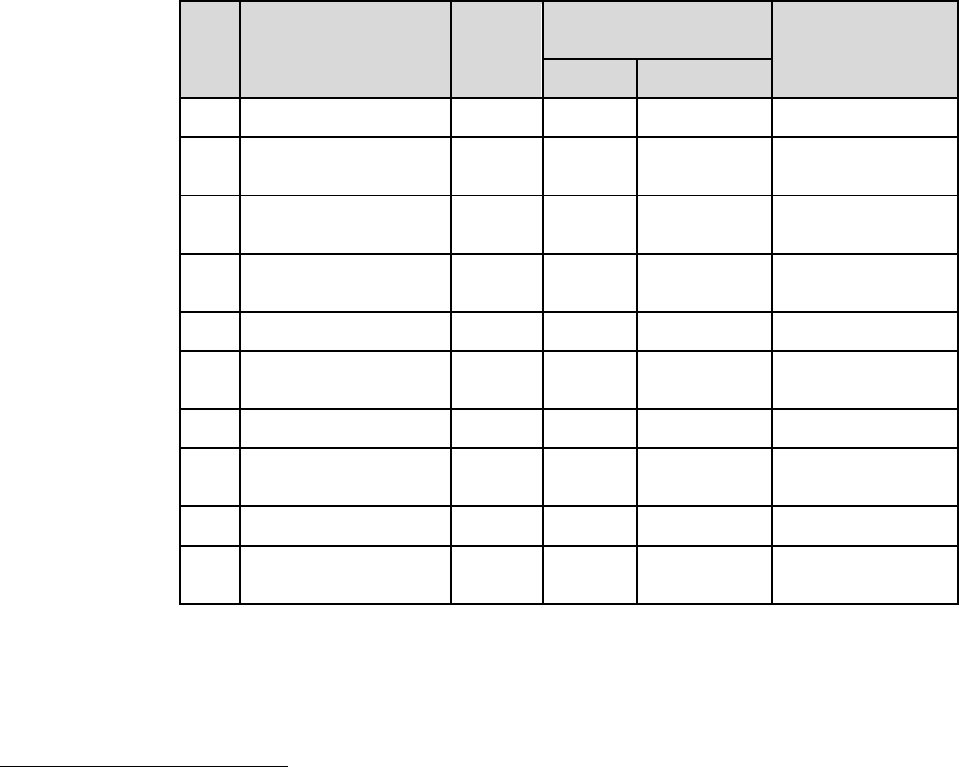

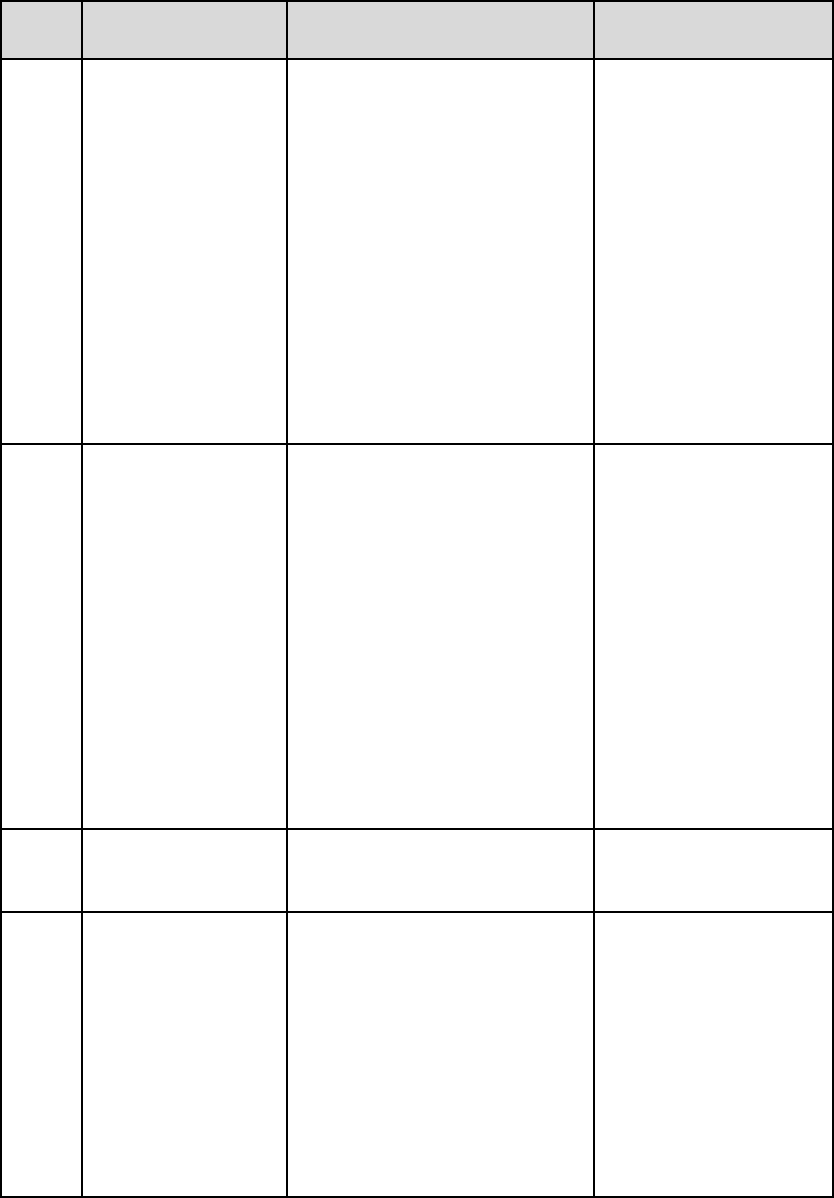

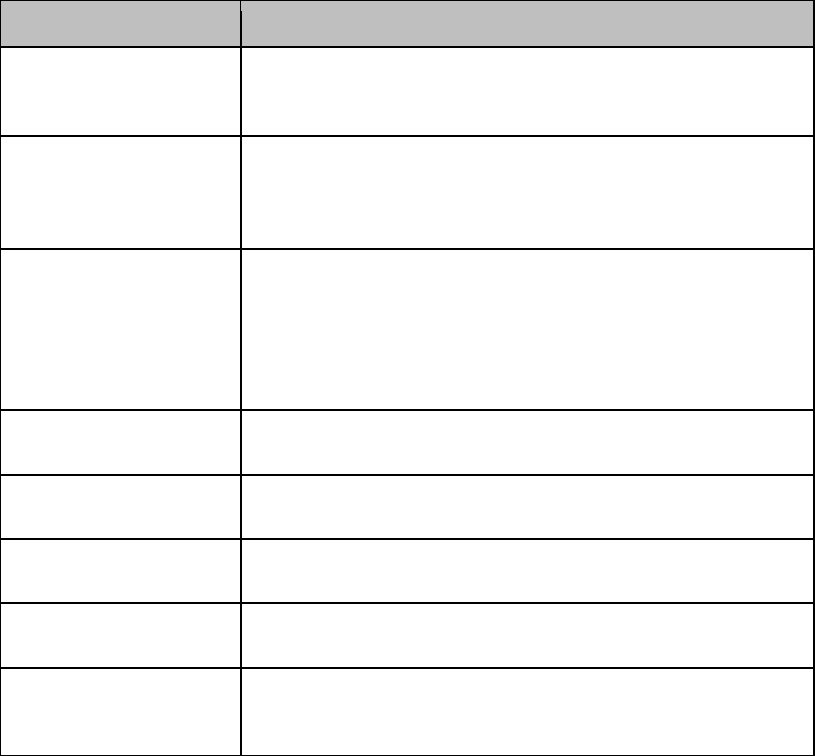

Table 1: Support

CPU Type

Minimum Firmware Version

Required

PACPAC Machine

Edition Support

CPL410

Any

Release 9.50 SIM 10

CPE400

Release 9.30 Build E8JL

Release 9.50 SIM 5

CPE330

Release 8.70 Build E5KG

Release 8.60 SIM 8

Figure 1: Rack-Mounted CPU with RMX Redundancy Communications Links

1

Exception: A CPE330 replacing a CRU320 in a redundant system may be paired with a CRU320. This should be considered a temporary

arrangement. See notes in Section 6.2.1 and Section 6.8.1.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 1

GFK-2308W May 2021

Introduction 3

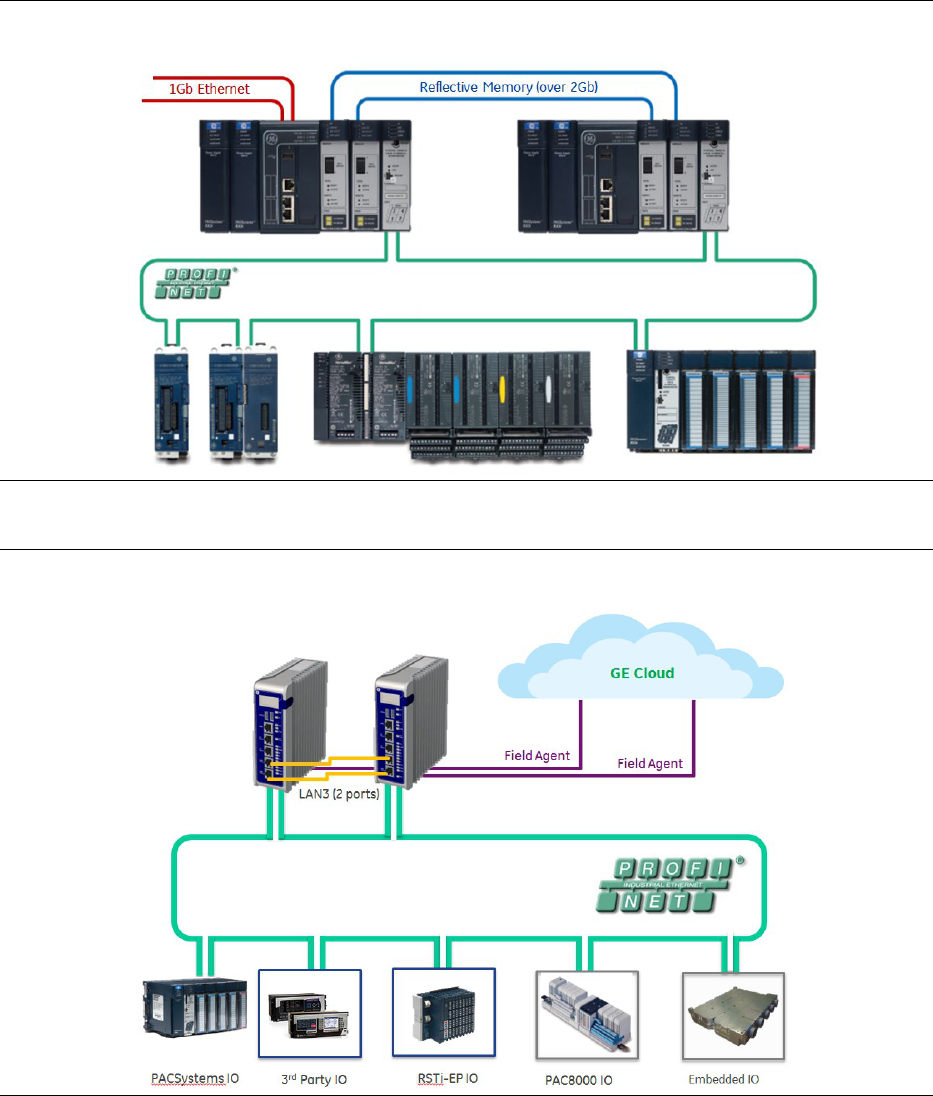

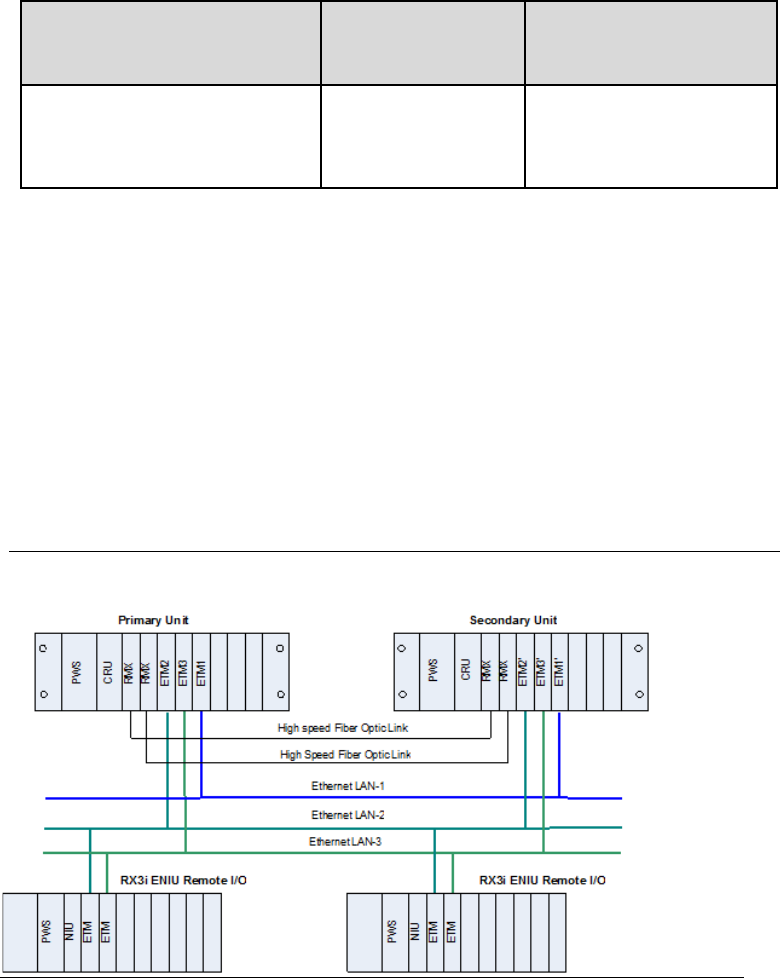

Figure 2: CPE330 Redundancy (Uses RXM modules for Redundancy Communications Link

Figure 3: CPE400 Redundancy (Uses LAN3 Ports for Redundancy Communications Link)

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 1

GFK-2308W May 2021

Introduction 4

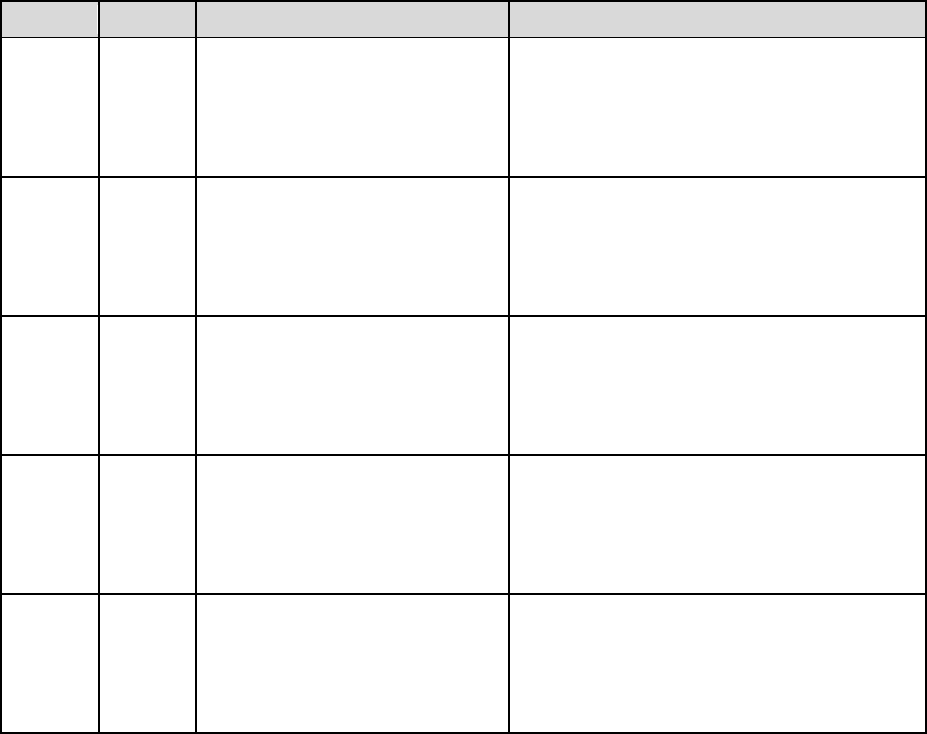

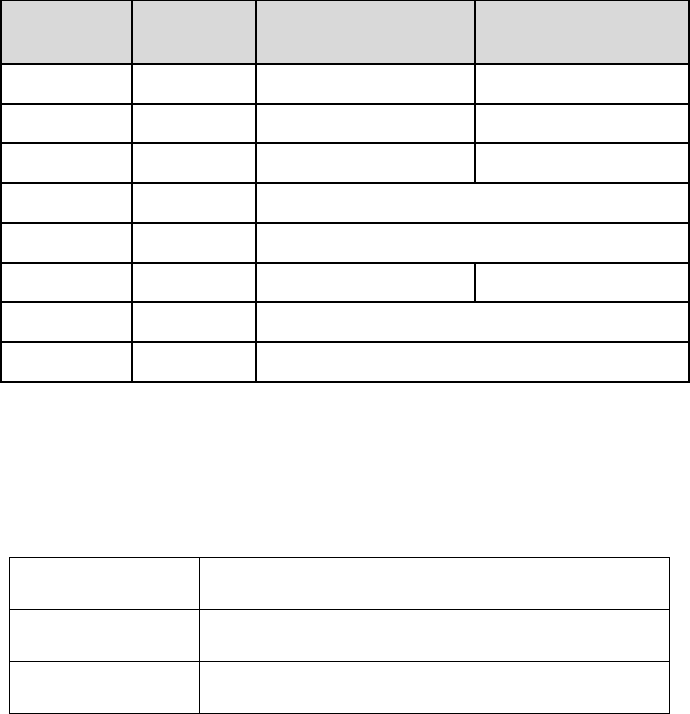

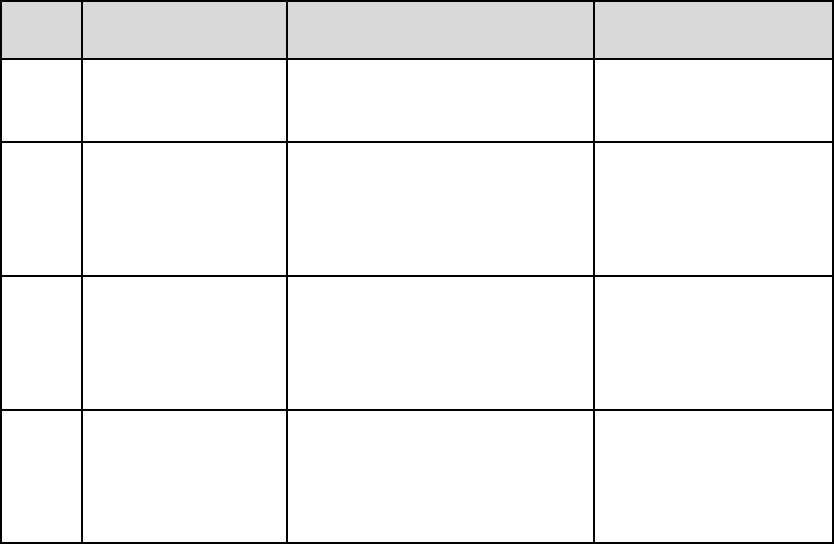

1.2 PACSystems HSB Redundancy Feature

Summary

Feature

RX3i Redundancy System

CPE330 Redundancy

System

CPE400 or CPL410

Redundancy System

Redundant CPU

IC695CRU320

IC695CPE330

IC695CPE400 or

IC695CPL410

Redundancy links

Two IC695RMX128 or

IC695RMX228 modules per link

Two links (four RMX modules)

recommended per system

Two IC695RMX128 or

IC695RMX228 modules

per link

Two links (four RMX

modules) recommended

per system

2

LAN3 RDN

(Uses two lower ports on

faceplate)

Two links recommended per

system

Redundancy I/O

systems supported

PROFINET I/O using single ring and

star network topologies

Single and redundant Ethernet

remote

I/O LANs through ENIU

Single Bus and Dual Bus Genius

networks

PROFINET I/O using single

ring and star network

topologies

Single and redundant

Ethernet remote

I/O LANs through ENIU

Single Bus and Dual Bus

Genius networks

PROFINET I/O using single ring

and star network topologies

FUTURE: Single and redundant

Ethernet remote

I/O LANs through ENIU

Expansion and

remote racks

Supported

Supported

Not Supported

Failure recovery

Survives any one single point of

failure (excluding failures of Genius

devices and bus stubs)

Online repair of failed component

Survives any one single

point of failure (excluding

failures of Genius devices

and bus stubs)

Online repair of failed

component

Survives any one single point

of failure

Online repair of failed

component

Role switching

Manual toggle switch for switching

control between Active and

Backup units

Application-initiated role switching

Manual toggle switch for

switching control between

active and backup units

Application-initiated role

switching

OLED Display command for

switching control between

active and backup units

Application-initiated role

switching

2

While two links are recommended in a CPE330 Redundancy System, as of PME Release 9.5 SIM14 and firmware 9.75, the system can

be configured with only one link.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 1

GFK-2308W May 2021

Introduction 5

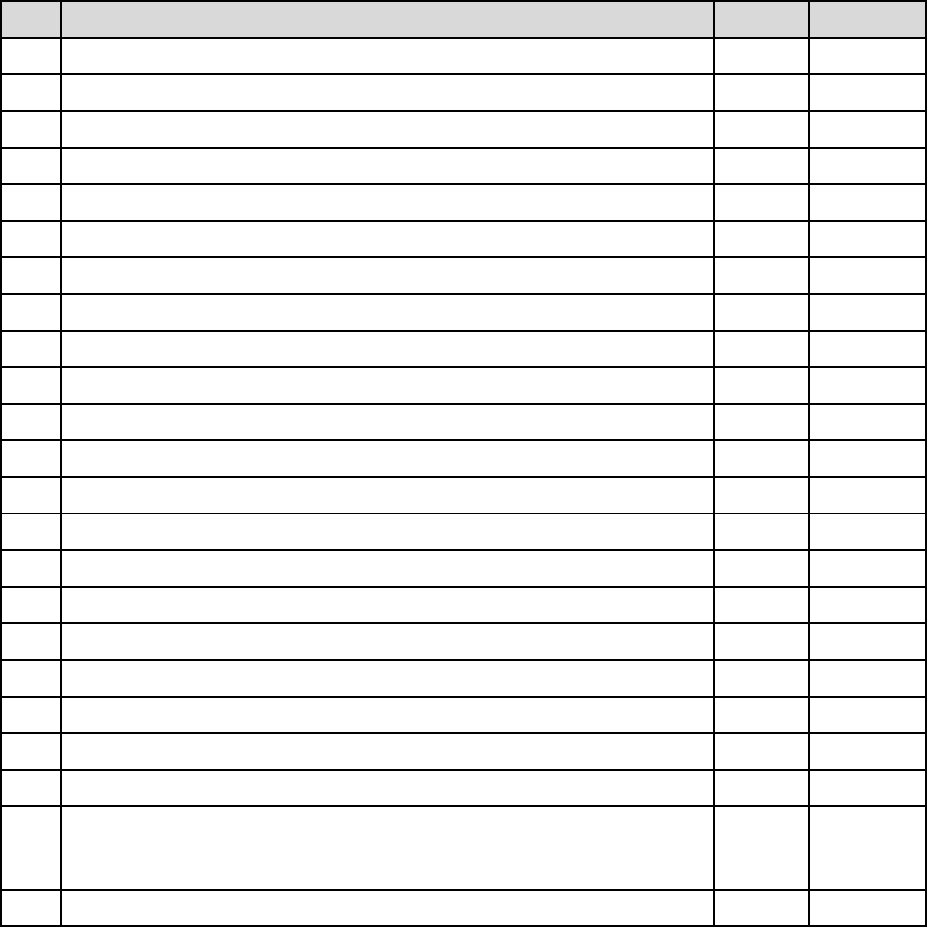

Feature

RX3i Redundancy System

CPE330 Redundancy

System

CPE400 or CPL410

Redundancy System

Bumpless switching

from Active unit to

Backup unit

Synchronized CPUs

One-scan switching

Configurable transfer data size up

to 2Mbytes

Synchronized CPUs

One-scan switching

Configurable transfer data

size up to 2Mbytes

Synchronized CPUs

One-scan switching

Configurable transfer data size

up to 2Mbytes

Redundancy status

monitoring

RMX128/RMX228 module has five

redundancy status LEDs (Link OK,

Local Ready, Local Active, Remote

Ready, Remote Active)

Redundancy status bits and

message logging

RMX128/RMX228 module

has five redundancy status

LEDs (Link OK, Local

Ready, Local Active,

Remote Ready, Remote

Active)

Redundancy status bits

and message logging

OLED Display provides

redundancy state. CPE400 &

CPL410 also include two

redundancy status LEDs: RACT

(Local Unit Ready & Active),

and RBOK (Remote Unit

Ready)

Redundancy status bits and

message logging

Online programming

Supported

Supported

Supported

Diagnostics

Background diagnostics

Memory error checking and

correction (ECC) with single bit

corrections and multiple bit

checking

Background diagnostics

Memory error checking

and correction (ECC) with

single bit corrections and

multiple bit checking

Background diagnostics

Memory error checking and

correction (ECC) with single

bit corrections and multiple

bit checking

Maximum fiber-optic

cable distance

supported between

two devices used in

redundancy link

RMX128: 1000 ft (304.8m)

RMX228: 6.2 mi (10 km)

RMX128: 1000 ft (304.8m)

RMX228: 6.2 mi (10 km)

100 meters (328 ft).

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 1

GFK-2308W May 2021

Introduction 6

1.3 Online Programming

On-line changes to the application program are permitted in both the Active unit and

the Backup unit. The programming device must be connected to the unit in which

changes are to be made in order to make any on-line changes.

PACSystems releases 5.5 and later supports Run Mode Store (RMS) of the redundancy

Transfer List. This capability allows you to add, delete or modify Transfer List entries

without stopping the controllers.

Run Mode Store is performed independently on each controller. However, in a

synchronized system, the optional Dual RMS with Simultaneous Activation feature can

be used to defer activation of the newly stored application data until an RMS has

been performed on both units. Because the controller sweeps are synchronized, both

units will activate the new logic and transfer lists on the same sweep. For additional

information about the use of this feature, refer to Section 5.7, Run Mode Store.

1.4 Online Repair and System Upgrade

A Hot Standby CPU Redundancy system permits online repair of failed components

without disrupting the control application. A failed component can be replaced in

either unit after first removing power from the defective CPU system.

After replacing the component, returning power to the CPU system, and placing the

CPU in Run mode, the repaired unit synchronizes with the currently Active unit. Upon

successful synchronization, the repaired unit becomes the Backup unit.

1.5 Definitions

Active Unit

The unit that is currently controlling the process.

Backup Unit

The unit that is synchronized with the Active unit and able to take over the process.

CPU Redundancy

A system with two controller CPU units cooperating to control the same process.

Critical

Component

Components that acquire or distribute I/O data or that are involved in execution of

the control logic solution.

Critical Network

Port

An Ethernet port connection on the PROFINET I/O Controller that is configured as a

critical port. When the last Critical Network Port is disconnected from its network, a

diagnostic fault is logged. In a redundancy system where the PROFINET I/O Controller

is controlling redundant devices, this results in a CPU redundancy role switch with the

CPU placed into Stop/Fault mode.

EGD

Ethernet Global Data.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 1

GFK-2308W May 2021

Introduction 7

ENIU

Ethernet Network Interface Unit

Note that an Ethernet redundancy system (single and redundant Ethernet remote

I/O) may be implemented using one of the many ENIU Machine Edition templates

that are available. The template matches the physical Ethernet configuration and I/O

points involved. An application program is loaded into the CPU to perform the

redundancy functionality.

GBC

Genius Bus Controller: An interface module that is located in a CPU system and

controls communications on a Genius Bus.

Genius Dual Bus

The use of two Genius busses to control the same I/O devices. The busses are linked

to the I/O devices by one or more Bus Switching Modules (BSMs). A BSM will

automatically switch to the other bus if the active bus has a failure.

Genius Hot

Standby

A feature of Genius devices whereby the device prefers output data from the bus

controller at SBA 31. When outputs from that bus controller are not available, the

device takes output data from the bus controller at SBA 30. If outputs from neither

controller are available, the device places its outputs in the designated default state.

GNIU

Genius Network Interface Unit

Hot Standby

A system where the Backup (Hot Standby) unit is designated before any critical

component failure takes place, and all necessary state/control information is passed

from the Primary to this designated Backup unit so that it can take control quickly in

the event of a critical component failure.

Non-

Synchronized

Active Unit

(NSAU)

A CPU in a Redundancy System that is in Run mode but not synchronized with a

Backup unit. The Backup unit is either offline (in Stop mode, powered off, or failed),

or there are no functional redundancy links between the two CPUs.

OPC UA

OPC Unified Architecture (OPC UA) is a machine to machine communication protocol

for industrial automation developed by the OPC Foundation.

Primary CPU

The preferred unit to control the process in a Redundancy System. For redundant

Genius I/O, the Genius Bus Controllers installed in the Primary CPU are configured for

serial bus address (SBA) 31.

Redundancy

The use of multiple elements controlling the same process to provide alternate

functional channels in case of failure.

Redundancy Link

A complete communications path between the two CPUs for the purpose of

exchanging Redundancy data. CPE400 and CPL410 provide this link via a pair of

dedicated Ethernet ports (LAN3). For rack-mounted CPUs, the link consists of one

RMX in the Primary CPU rack and one RMX in the Secondary CPU rack. The RMX units

communicate via an interconnecting high-speed fiber-optic cable.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 1

GFK-2308W May 2021

Introduction 8

Redundant IP

Address

An IP address that is assigned to the pair of Ethernet interfaces in the Primary and

Secondary CPU systems. All data sent to the redundant IP address (including EGD

produced to the redundant IP address) is handled by the Active unit.

Role Switch

User-initiated switch of control, where the Active unit becomes the Backup unit and

the Backup unit becomes the Active unit.

SBA

Genius Serial Bus Address: a unique address (0-31) assigned to any device on the

Genius Bus.

Secondary CPU

The unit configured to control the process in a Redundancy System when the Primary

CPU is unavailable or otherwise marked as not controlling the process. For redundant

Genius I/O, the Genius Bus Controllers installed in the Secondary CPU are configured

for SBA 30.

Synchronized

Condition where both units are in Run Mode and the Backup unit has received the

latest status and synchronization information from the Active unit via a redundancy

link. When the two units are synchronized, they run their logic solution in parallel. If

the Active unit goes offline, control of the redundancy outputs is switched in a

bumpless fashion (without interruption) to the Backup unit.

Transfer List

The ranges of references that will be transferred from the Active unit to the Backup

unit. The transfer list is selected in the hardware configuration for the Redundant

CPU.

1.6 PROFINET Definitions

AR

Application Relationship. PROFINET term for a relationship that is established between an IO-

Controller/Supervisor and IO-Device. For any data to be exchanged between an IO-

Controller/Supervisor and a given IO-Device, an Application Relationship must be established.

Within the Application Relationship, various Communication Relationships (CRs) are then

established for the different types of data to be exchanged.

Broadcast

In Ethernet, the transmission of a network message to all hosts on the network.

CLI

Command Line Interface

CPU Node

In a PACSystems RX3i PROFINET network, a CPU Node is a node in which a PACSystems RX3i CPU

is connected to the PROFINET network.

CR

Communication Relationship. PROFINET term for a channel that is established within an

Application Relationship (AR) to transfer specific data between an IO-Controller/Supervisor and a

given IO-Device. Multiple CRs are established within an AR to transfer data.

Critical Network

Port

An Ethernet port connection on the PROFINET I/O Controller that is configured as a critical port.

When the last Critical Network Port is disconnected from its network, a diagnostic fault is logged.

In a redundancy system where the PROFINET I/O Controller is controlling redundant devices, this

results in a CPU redundancy role-switch with the CPU placed into Stop/Fault mode.

DAP

Device Access Point. This access point is used to address an IO-Device as an entity.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 1

GFK-2308W May 2021

Introduction 9

DEVICE

In PROFINET IO, the term Device refers to a PROFINET IO Device (IOD).

Gratuitous ARPs

An Address Resolution Protocol (ARP) request sent by the host to resolve its own IP Address.

GSDML

General Station Description Markup Language - definition of PROFINET Device Characteristics.

IOC

PROFINET IO-Controller

IOD

PROFINET IO-Device

IOCR

Input Output Communication Relationship – describes the type (input/output) and amount of

I/O data to be transferred, the sequence of the transfers and the transfer cycle between a

PROFINET IO-Controller (or IO-Supervisor) and a PROFINET IO-Device.

IOCS

PROFINET Input/Output Consumer Status is transmitted on the PROFINET network to provide

feedback on Input Data for an IO controller and Output Data for an IO device.

IOPS

PROFINET Input/Output Provider Status is transmitted on the PROFINET network to provide

feedback on Output Data for an IO controller and the Input Data for an IO device.

IOxS

PROFINET abbreviation for the IOCS and/or IOPS (see above).

LLDP

Link Layer Discovery Protocol. IEEE standardized protocol used by network devices to advertise

their identity and capabilities.

LLDPDU

Link Layer Discovery Protocol Data Unit.

MAC

Media Access Control address (MAC address)

MAU

Medium Attachment Unit

MIB

Management Information Basis

MRC

Media Redundancy Client. Within Media Redundancy Protocol, an MRC is responsible for helping

the MRM detect breaks/no breaks in the ring.

MRM

Media Redundancy Manager. Within Media Redundancy Protocol, an MRM is responsible for

ensuring that the ring does not have a closed loop, while simultaneously ensuring maximal

connectivity between nodes on the ring. There must be exactly one MRM in the Ring network.

MRP

Media Redundancy Protocol. An Ethernet protocol that provides redundant paths for PROFINET-

IO cyclic traffic by supporting a ring topology.

Multicast

In Ethernet, the transmission of a network message to all hosts within a host group.

NOS

Name of Station

OID

Object Identifier

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 1

GFK-2308W May 2021

Introduction 10

Glossary, continued

Phase

If the IOCR Update Period is greater than the Send Clock time, the Update Period is divided into

multiple phases where each phase is equal to one Send Clock.

PHY

PHY is an abbreviation for the physical layer of the OSI model and refers to the circuitry required

to implement physical layer functions. A PHY connects a link layer device (often called MAC as an

abbreviation for medium access control) to a physical medium such as an optical fiber or copper

cable.

PNC

PROFINET Controller: Typically, the generic PROFINET Controller function. PNC001 represents a

slot-mounted product (IC695PNC001). Embedded PROFINET Controllers may be configured on

LAN2 for CPL410, CPE400, CPE330 and CPE100. Both embedded and slot-mounted perform the

same functions on the PROFINET network, but there are differences to be noted in installation,

configuration, operation and performance.

PNS

PROFINET Scanner. Head-end module that controls I/O in rack and communicates with PROFINET

network. Both RX3i (IC695PNS001) and VersaMax (IC200PNS001, IC200PNS002) modules are

discussed in this manual. IC695PNS101 is similar to IC695PNS001, but is normally restricted to

RX3i Sequence of Events applications. IC695CEP001 performs a similar function to IC695PNS001,

but without use of RX3i I/O racks. Refer to documentation for IC695PNS101 and IC695CEP001.

PNSR

PROFINET System Redundancy. PNSR is the combination of PROFINET processes and

mechanisms by which an IO-Device is controlled by multiple IOCs in redundant PLCs.

Primary AR

In PROFINET System Redundancy, the AR to a Redundant Device that currently provides IO Data

Transfer and control.

RDHT

Redundancy Data Hold Time: The maximum time that the IO Device waits for a Controller to take

control of the AR connection during an IO switchover.

RDO

Record Data Object. Services used to read and write structured data stored in a PROFINET IO-

Device.

Reduction Ratio

Along with Send Clock determines the Update Period for a PROFINET cyclic data transfer between

two devices (see IOCR). The Update Period equals the Reduction Ratio multiplied by the Send

Clock time. For example, if the Reduction Ratio is 4 and the Send Clock is 1ms, the Update Period

is 4ms.

Remote Node

For an RX3i PROFINET network, a Remote Node is any PROFINET IO-Device, such as a rack of I/O

modules with a Remote Scanner or a third party PROFINET IO-Device.

RIV

Reference ID Variables

RTA

Real-Time Acyclic. A PROFINET-IO Mechanism used to exchange non-periodic data such as

alarms.

RTC

Real-Time Cyclic. A PROFINET-IO Mechanism used to exchange input and output data.

Send Clock

Value between 1 and 128 inclusive in units of 31.25 µs (equivalent to a range of 31.25 µs to 4 ms)

used to calculate the Update Period for a PROFINET cyclic data transfer between two devices (see

IOCR). The Send Clock is the basis for all other scheduling parameters.

Send Offset

The time to delay a scheduled PROFINET cyclic data transfer frame.

Measured in nanoseconds from 0 to 3,999,999. Must be less than the Send Clock time.

SFP

Small Form-factor Pluggable. Pluggable, hot-swappable transceivers.

SNMP

Simple Network Management Protocol. UDP-based network protocol that facilitates the

exchange of management information between network devices.

Status Bits

Module status data in RX3i CPU reference memory.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 1

GFK-2308W May 2021

Introduction 11

Submodule

PROFINET-IO representation of the smallest configurable entity of a PROFINET Module.

SVC_REQ

Service Request Function Block. A control system service initiated by the RX3i CPU.

TLV

Type-Length-Value

Unicast

In Ethernet, the transmission of a network message to an individual host.

Update Period

The time between PROFINET cyclic data transfers between an IO-Controller and an IO-Device.

WinLoader

A software utility used to download and install firmware upgrades.

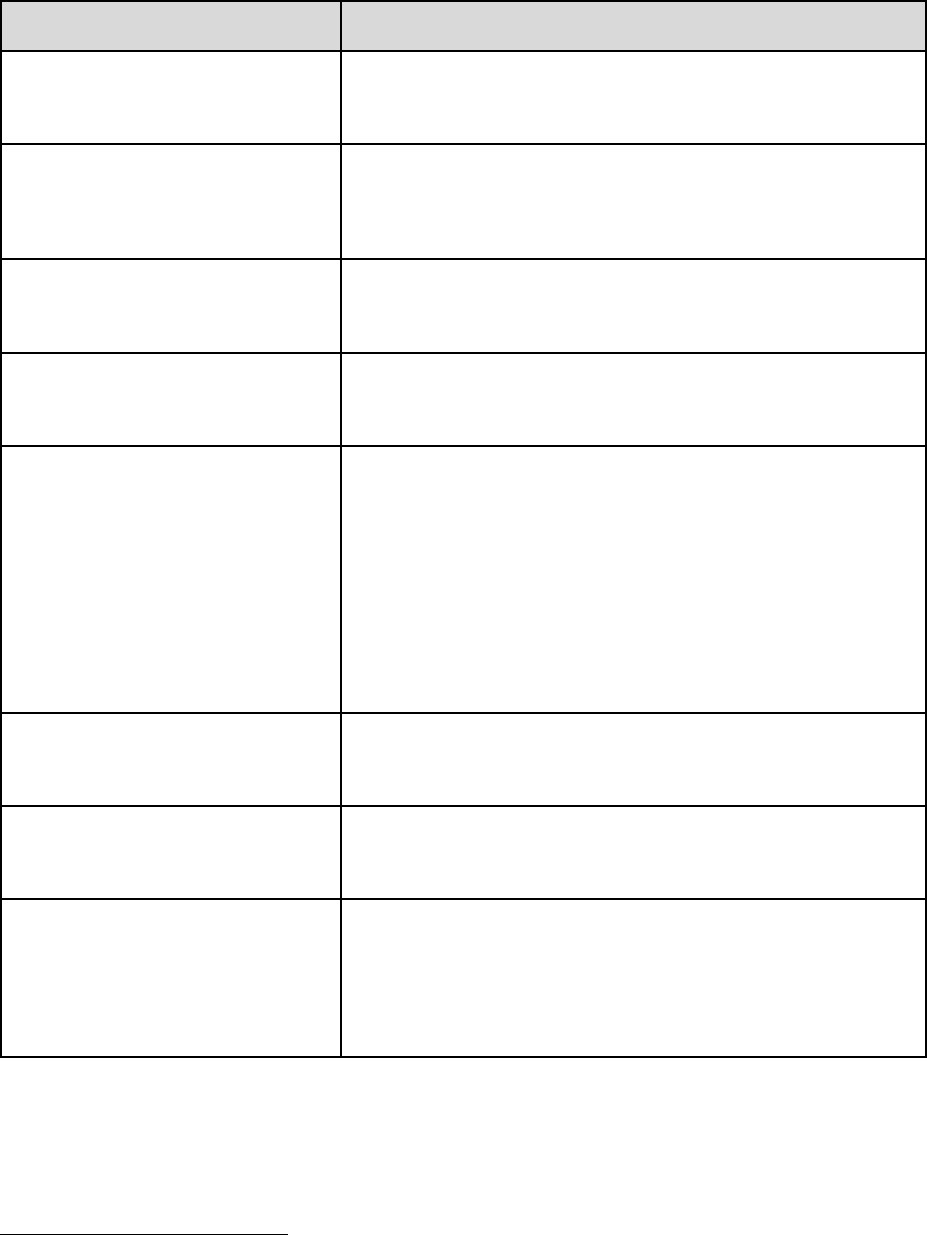

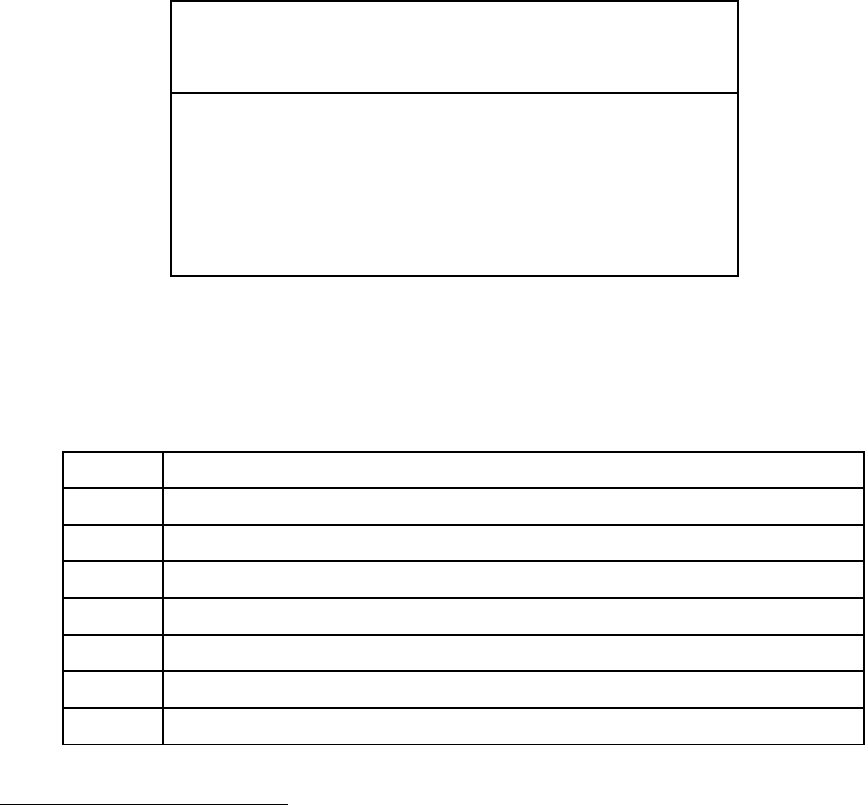

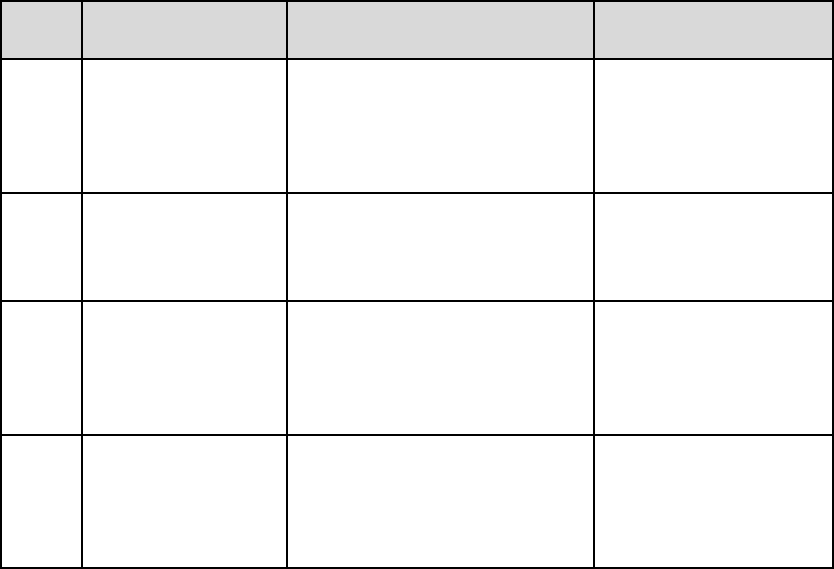

1.7 Revisions in this Manual

Rev

Date

Description

W

May

2021

▪ Updates regarding the number of supported PROFINET devices for the CPL410

V

Jan

2021

▪ Added Section OPC UA

U

June

2020

▪ Correction made to catalog number of supported RSTI-EP PROFINET Scanner in Table 2

▪ Updated cover page image of RX3i rack

▪ The source IP address used to produce EGD in a system using a redundant IP address is

now configurable

T

Mar-

2020

▪ Added section Redundant I/O Wiring Details And Programming Strategies as

Appendix D

R

Aug-

2019

▪ Updates related to RX3i Firmware Release 9.90

▪ Addition of ETM-Kxxx

Q

Mar-

2019

▪ Updates related to RX3i Firmware Release 9.40

P

Jul-

2018

▪ Dual RMX configuration is no longer required for the CPE330 with PME SIM14 or later

and firmware 9.75 or later. This also applies to the CPE330 when it is in CRU320

compatibility mode

N

Jul-

2018

▪ Addition of IC695CPL410 (new CPU)

▪ Addition of IC695PNS101 (PROFINET Scanner for RX3i Sequence of Events)

M

Mar-

2018

▪ Updates related to RX3i Firmware Release 9.40

L

Oct-

2017

▪ Added information related to CPE330 and CPE400 CPUs

▪ Documentation of CPE400 LAN3 usage as dedicated Redundancy Link

▪ Step-by-step instructions modified for rack-less systems (CPE400) vs rack-mounted

systems (all others)

K

Jan-

2015

▪ Added/modified information to include PNC critical network port feature.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 1

GFK-2308W May 2021

Introduction 12

1.8 Documentation

1.8.1 RX3i Manuals

PACSystems RX3i System Manual

GFK-2314

PACSystems RX3i Max-On Hot Standby Redundancy User’s Manual

GFK-2409

PACSystems RX3i PROFINET Scanner Manual

GFK-2737

PACSystems RX3i CEP PROFINET Scanner User Manual

GFK-2883

PACSystems RX3i Genius Communications Gateway User Manual

GFK-2892

PACSystems RX3i IC695CPE400 1.2GHz 64MB Rackless CPU w/Field Agent Quick Start

Guide

GFK-3002

PACSystems RX3i IC695CPL410 1.2GHz 64MB Rackless CPU w/Linux Quick Start Guide

GFK-3053

1.8.2 VersaMax Manuals

VersaMax PROFINET Scanner Manual

GFK-2721

In addition to these manuals, datasheets and product update documents describe individual modules and

product revisions. The most recent PACSystems documentation is available on the support website provided

at the link at the end of this document.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 2

GFK-2308W May 2021

RX3i Hot Standby Redundancy Quick Start with PROFINET I/O 13

Section 2: RX3i Hot Standby Redundancy

Quick Start with PROFINET I/O

This chapter provides the steps needed to set up and configure a basic RX3i Hot

Standby CPU Redundancy system that uses PROFINET I/O.

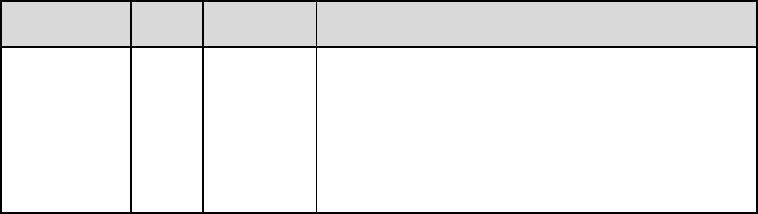

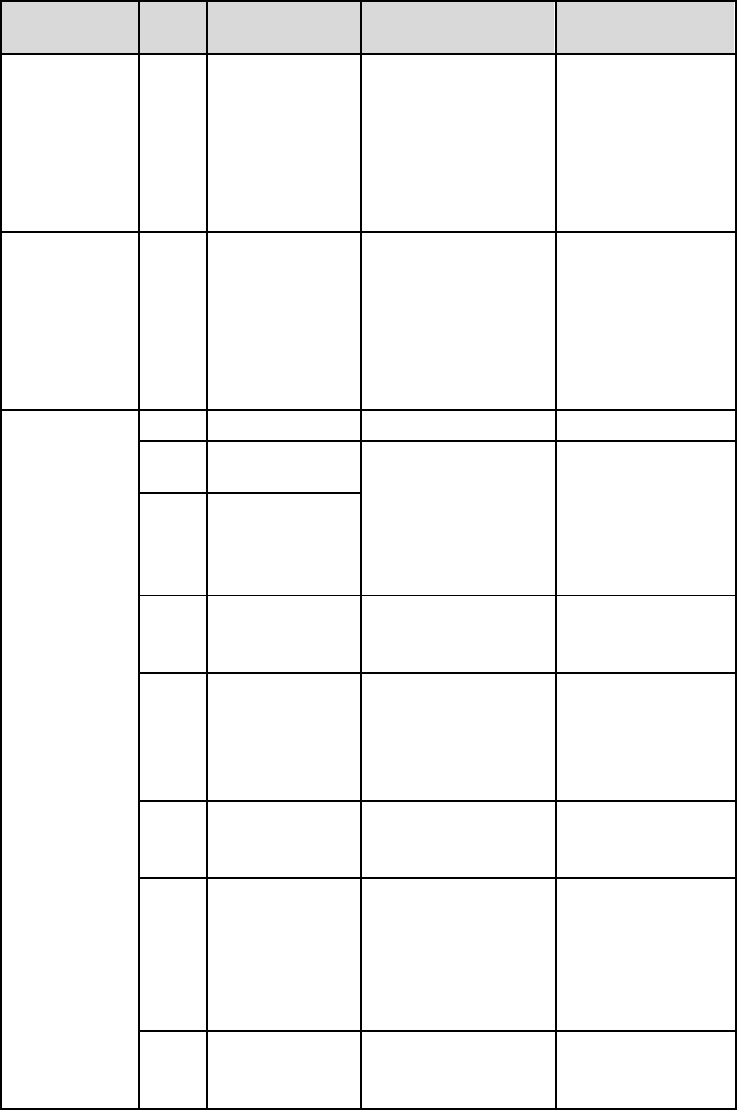

The following table shows which PROFINET Scanners/Devices support PACSystems

Hot Standby CPU Redundancy.

Table 2: PROFINET Scanners/Devices that Support PACSystems Hot Standby CPU

Redundancy

PROFINET Scanner/Device

Catalog

Number

Simplex

Controllers

RX3i Hot Standby CPU

Redundancy

RX3i CEP Carrier

IC695CEP001

X

X

RX3i Genius® Communications

Gateway

IC695GCG001

X

3

X

3

PAC8000 PROFINET Scanner (PNS)

Module

8515-BI-PN

8516-BI-PN

X

X

4

RSTi PROFINET Network Adaptor

STXPNS001

X

RSTi-EP PROFINET Scanner

EPXPNS101

X

X

RX3i PROFINET Scanner (PNS)

Module

IC695PNS001

X

X

RX3i PROFINET Scanner (PNS)

Module

for RX3i Sequence of Events

IC695PNS101

X

X

VersaMax PROFINET Scanner (PNS)

Module

IC200PNS001

IC200PNS002

X

X

VersaMax IP PROFINET Scanner

Module

IC677PNS001

X

VersaPoint PROFINET Scanner

IC220PNS001

IC220PNS002

X

3

Effective with firmware version 2.2.3.0, the Genius Communication Gateway supports Genius Dual Bus.

4

PAC8000 PROFINET Scanner v2.01 or later supports Hot Standby.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 2

GFK-2308W May 2021

RX3i Hot Standby Redundancy Quick Start with PROFINET I/O 14

System Design by Controller Selection The basic CPU system varies according to CPU

type:

Traditional Rack-Mounted Systems (Figure 1)

install one Redundant CPU, one Ethernet module

5

, two RMX modules, one PROFINET

I/O Controller module, and two Multifunctional 40W Power Supply modules into

each RX3i rack. The Ethernet modules will be used to connect the programmer to the

controllers. Continue through this chapter for instructions on how to set up such a

system.

CPE330 system (Figure 2)

The Ethernet functions may be performed by configuring the CPE330 to use its

embedded Ethernet features. The Power Supply, PROFINET I/O Controller and RMX

modules are required. Refer to the CPE330 Quick Start Guide, GFK-2941E or later for

Hot Standby Redundancy set up. Additional details are provided below.

CPE400 system (Figure 3) (Non-Rack-Mounted)

An independent external Power Supply is provided for each CPE400. To eliminate a

possible single point of failure, the two power supplies should be on different circuits.

RMX modules are not employed. The Redundancy Communications Link is

accomplished by interconnecting the LAN3/RDN (RJ-45) ports. Connect the upper of

these two ports in the Primary to the corresponding upper port in the Secondary.

Connect the lower of these two ports in the Primary to the corresponding lower port

in the Secondary. Note that no intervening network equipment is allowed on LAN3.

Refer to the PACSystems RX3i IC695CPE400 1.2GHz 64MB Rackless CPU w/Field Agent

Quick Start Guide, GFK-3002A or later for Hot Standby Redundancy set up. Additional

details are provided below.

CPL410 system (Same as Figure 3)

Similar to CPE400, the same configuration and rules apply as in a CPE400 system. Refer to

the PACSystems RX3i IC695CPL410 1.2GHz 64MB Rackless CPU w/Linux Quick Start Guide,

GFK-3053 or later for Hot Standby Redundancy set up.

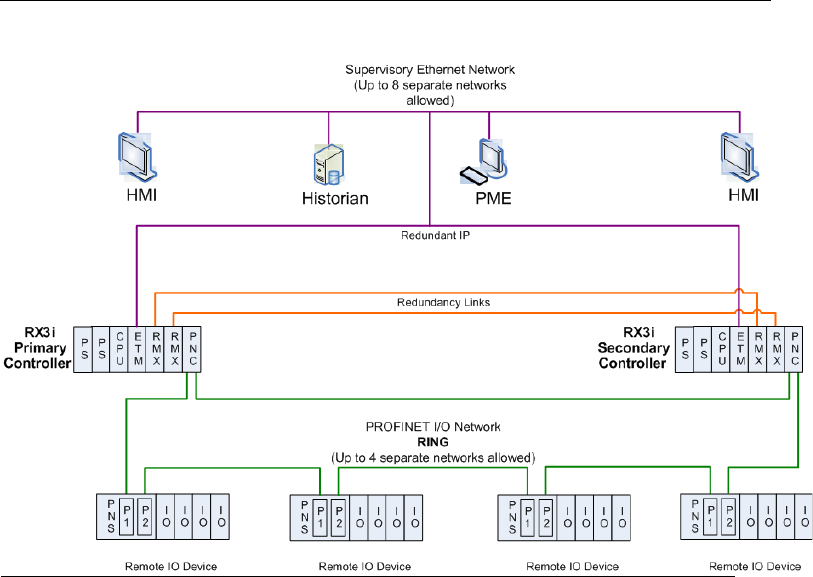

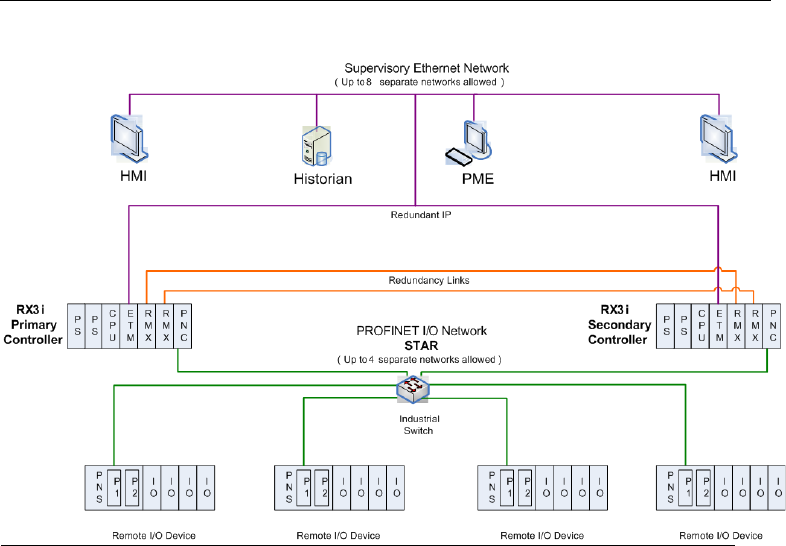

System Design Regardless of Controller Selection

In all cases, one controller is designated the Primary, and the other is designated the

Secondary.

In all cases, PROFINET is deployed using ring topology and consists of a pair of

PROFINET Controllers (PNCs), one in each CPU system, and at least one PROFINET

Scanner (PNS) module. The PNC itself is embedded in some cases and rack-mounted

in other cases.

RMX Modules

Where RMX modules are employed, use fiber-optic cables to connect each RMX module

in the Primary Rack to the corresponding RMX module in the Secondary Rack.

Using an LC-compatible fiber-optic cable, connect the TX connector on one RMX

module to the RX connector of the other RMX module and vice-versa (refer to Figure

4).

5

For details on the Ethernet module refer to the PACSystems RX3i and RSTi-EP TCP/IP Ethernet Communications

for PACSystems User’s Manual, GFK-2224.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 2

GFK-2308W May 2021

RX3i Hot Standby Redundancy Quick Start with PROFINET I/O 15

When power is applied, the RMX module performs an internal loopback test; during

this test, the RMX indicators OWN DATA and SIGNAL DETECT turn on briefly. Once

the RMX module is functioning normally, its OK indicator is on.

Figure 4: Fiber Optic Cable Connections for RMX module

Note: Ensure that the cable type matches the module type, such that, single-mode cable is

used for single mode modules and multimode cable is used for multimode modules.

1) (Applies to CRU320 only.) With the CPU battery disconnected, apply power to both

controller racks.

Each redundant CPU has Error Checking and Correcting (ECC) memory. For CRU320,

this must be initialized by applying power to the CPU with the battery disconnected

at least once. For CPL410, CPE400 and CPE330, ECC is always enabled and requires no

special initialization process.

2) (Applies to CRU320 only.) Connect a battery to each redundant CPU.

Because the ECC memory was initialized during step 1), the CPU can now be power cycled

with the battery connected.

3) Connect the PC that will be used to configure/program the controllers to the Ethernet

network.

4) Connect the PNCs and the PROFINET device(s) to a daisy chain line network similar to the

examples shown in Figure 1 through Figure 3, but do not form a complete ring yet. Leave

exactly one of the PROFINET network cables disconnected until the Primary PNC has

configuration data that tells it to act as the Media Redundancy Manager (step 11).

5) Create the Hardware Configuration (HWC).

a. Open PAC Machine Edition (PME), and create a target for an RX3i controller.

b. Select the Hardware Configuration node and expand.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 2

GFK-2308W May 2021

RX3i Hot Standby Redundancy Quick Start with PROFINET I/O 16

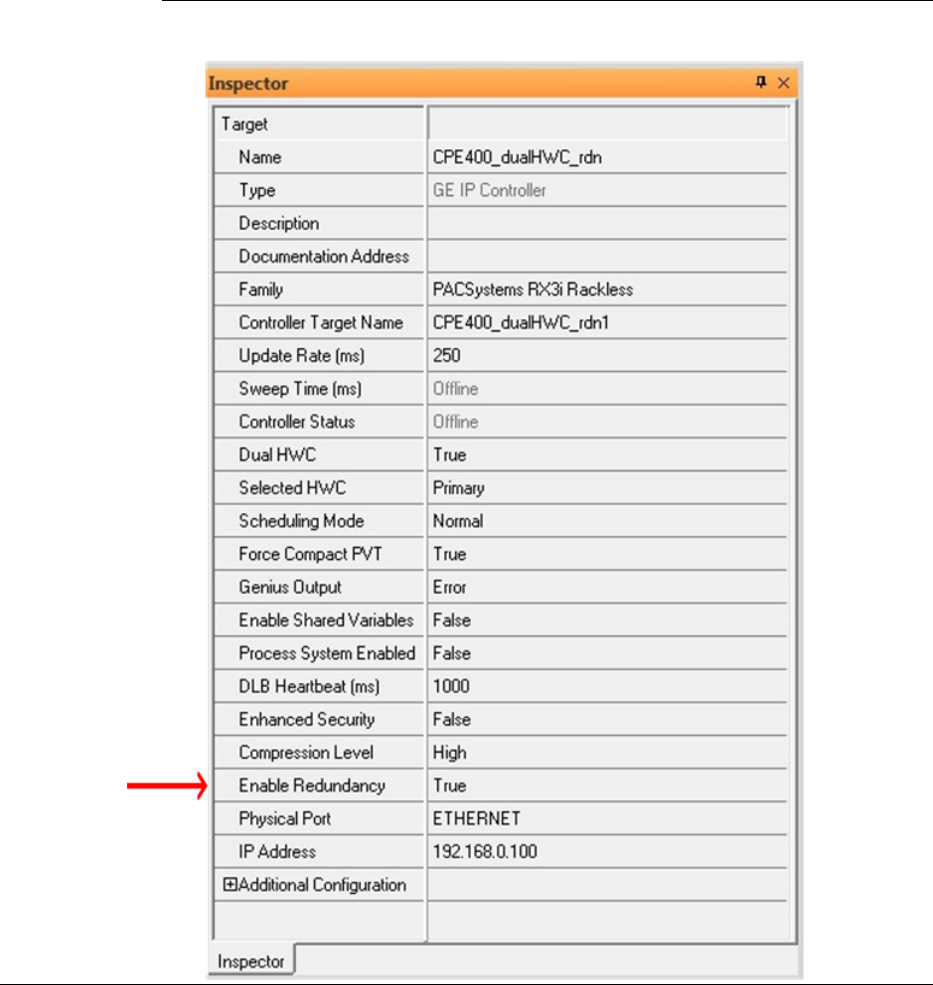

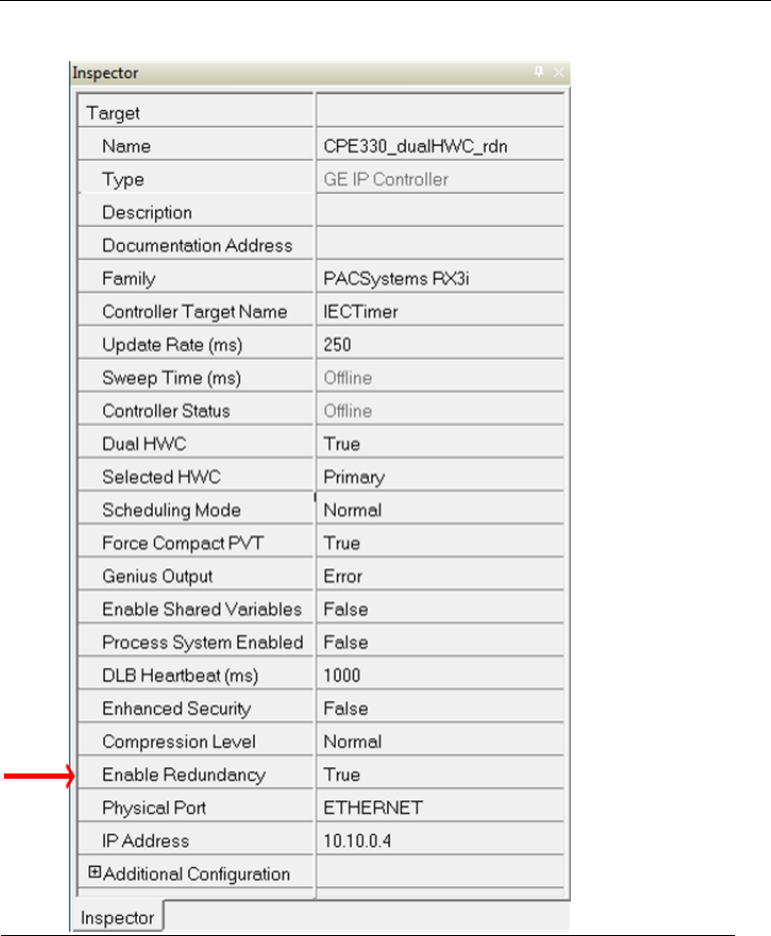

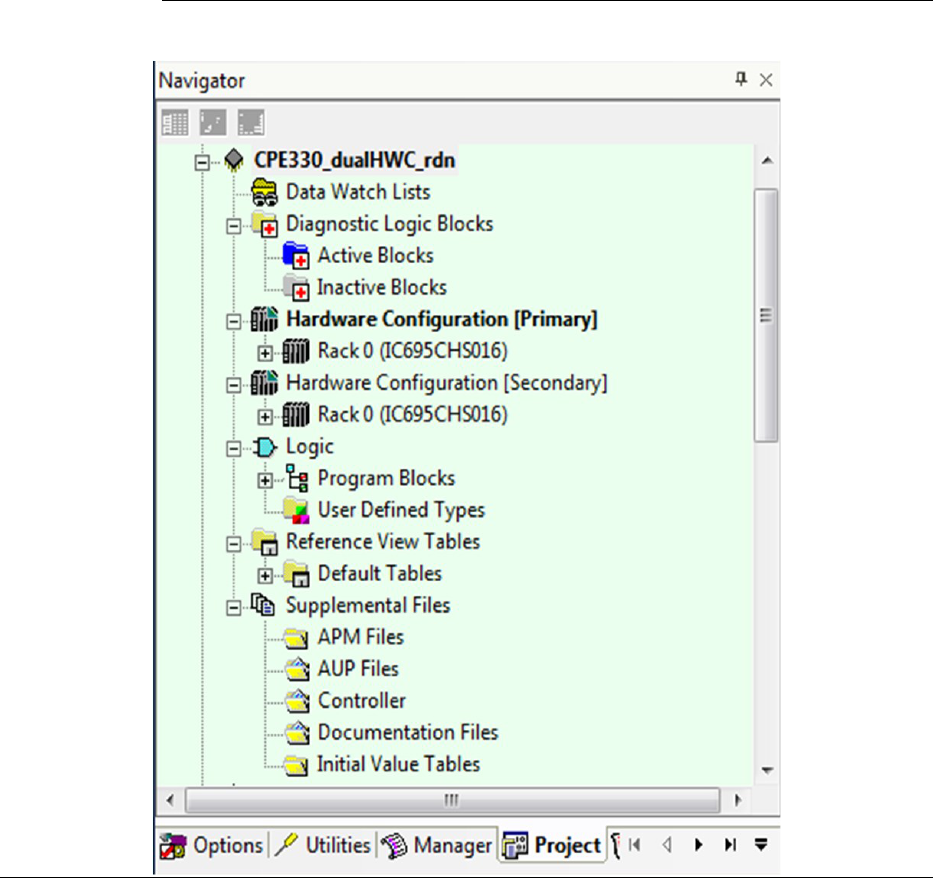

c. Replace the default CPU with whatever CPU is appropriate for your application

(CRU320, CPE330, CPE400 or CPL410, for example). If the CPU is a CRU320, PME will

automatically set the Dual HWC property for the target to True and creates a

‘Hardware Configuration [Secondary]’ node. For other CPUs it is necessary to set the

Enable Redundancy property to True. This will automatically add the Dual HWC

property and set it True.

d1. (For rack-mounted systems only.) Find the Rack 0 node under the

‘Hardware Configuration [Primary]’ node.

If this rack is not the correct size, right-click on it and select Replace Rack.

d2. (For rack-mounted systems only.) Expand the Rack 0 node that is under the

‘Hardware Configuration [Primary]’ node. Move the redundant CPU to the

correct slot within Rack 0.

d3. (For systems employing RMX modules only.) Add two RMX modules to this Rack 0.

e. Add a PNC to this CPU system. This can either be a physical PNC module located in

Rack 0, or (in the case of CPE330, CPE400 or CPL410) one of the CPU’s Ethernet

ports configured as an embedded PNC. PME automatically creates a new LAN named

LAN01 and attaches the PNC to that LAN. Set the proper subnet mask and range of

IP addresses for this LAN. Set the Network Transit Time parameter to 50 (= 5.0 ms,

which is recommended for MRP ring operation).

f. Configure the PNC module (or embedded PNC):

i. Assign a unique name and IP address for this PNC.

ii. Set this PNC’s Media Redundancy parameter to Manager.

iii. In order to fail-over to the Backup PLC if both PNC MRP ports are

disconnected, set the ports used for MRP to Network Port # Critical =

True (the 2nd MRP port will auto-select when the first MRP port is

selected).

g. If you have not already assigned a network name to each of your PROFINET devices,

do so now. You can do this by right-clicking on a PNC and selecting Launch

Discovery Tool. For more information, refer to the PACSystems RX3i PROFINET IO

Controller Manual, GFK-2571, Chapter 3, Configuration - Assigning IO-Device Names.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 2

GFK-2308W May 2021

RX3i Hot Standby Redundancy Quick Start with PROFINET I/O 17

h. Add each of your PROFINET Scanner (PNS) devices to the HWC by doing the following

for each device:

i. Right-click on the PNC in the ‘Hardware Configuration [Primary]’ HWC

and select Add IO-Device.

ii. Select the desired device from the Device Catalog.

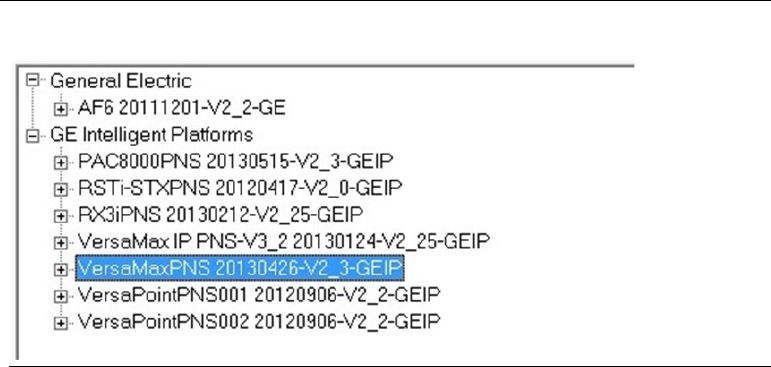

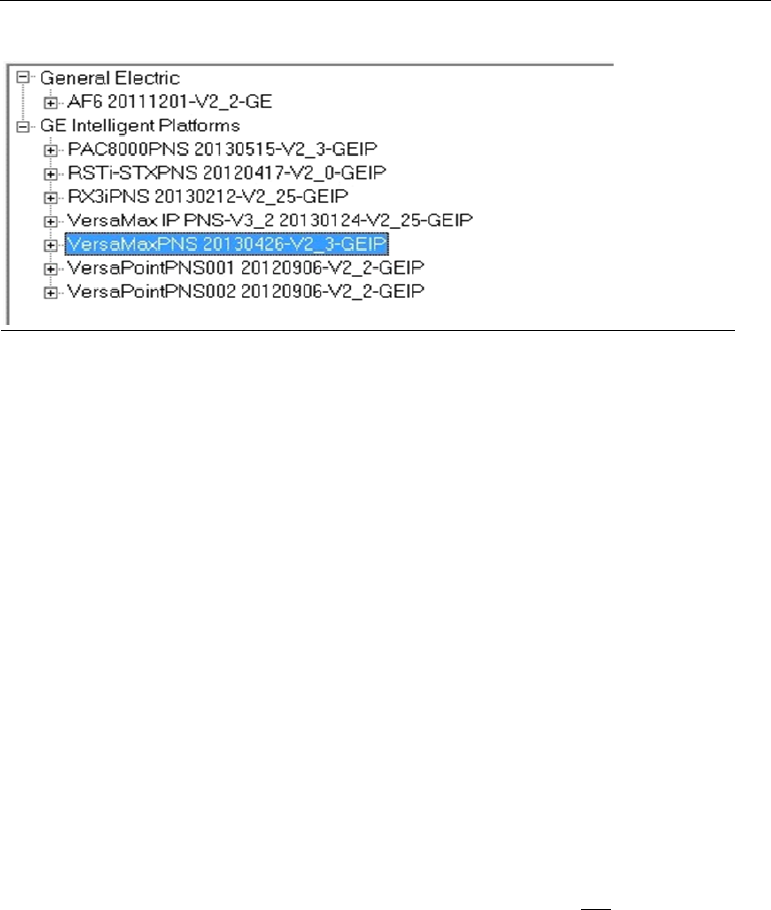

Figure 5: Select Device from the PMC Catalog

Be sure to select a PNS node that has V2_3 in its name. (A GSDML file of version 2.3 or

higher is required in order to configure the device to be redundantly controlled.)

iii. Because the device supports controller redundancy, PME will

automatically set the device’s Redundancy Mode parameter to HSB CPU

Redundancy.

iv. PME will assign a default name to the device. Be sure to change the

device’s name to match the name you assigned to it during step 9).

v. Add all appropriate I/O carriers (VersaMax only) and I/O modules to the

device’s configuration and set all of the configuration parameters to

appropriate values. For more information about configuring the PNS,

refer to the associated user manual:

▪ VersaMax PROFINET Scanner Manual, GFK-2721A

▪ RX3i PROFINET Scanner Manual, GFK-2737

▪ CEP PROFINET Scanner Manual, GFK-2883

Note: As you assign reference addresses to your redundantly controlled devices, PME

will automatically expand the Primary CPU’s input transfer list to include all

redundantly controlled PROFINET inputs. PME will also automatically expand the

Primary CPU’s output transfer list to include all redundantly controlled PROFINET

outputs.

i. For rack-mounted systems only: Add, replace, and/or move additional RX3i rack

modules to the ‘Hardware Configuration [Primary]’ HWC as needed. Examples of

these modules include power supplies and Ethernet modules. For each Ethernet

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 2

GFK-2308W May 2021

RX3i Hot Standby Redundancy Quick Start with PROFINET I/O 18

module, assign a unique IP address. For CPUs that have no rack-mounted hardware,

make all similar adjustments before proceeding to the next step.

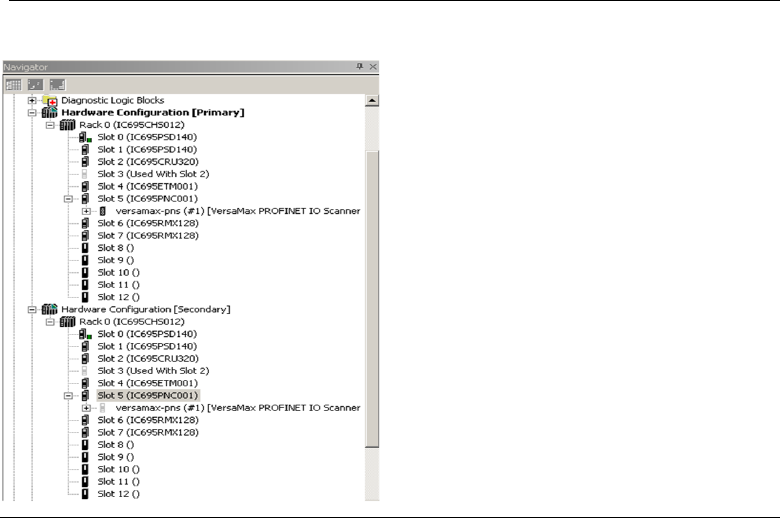

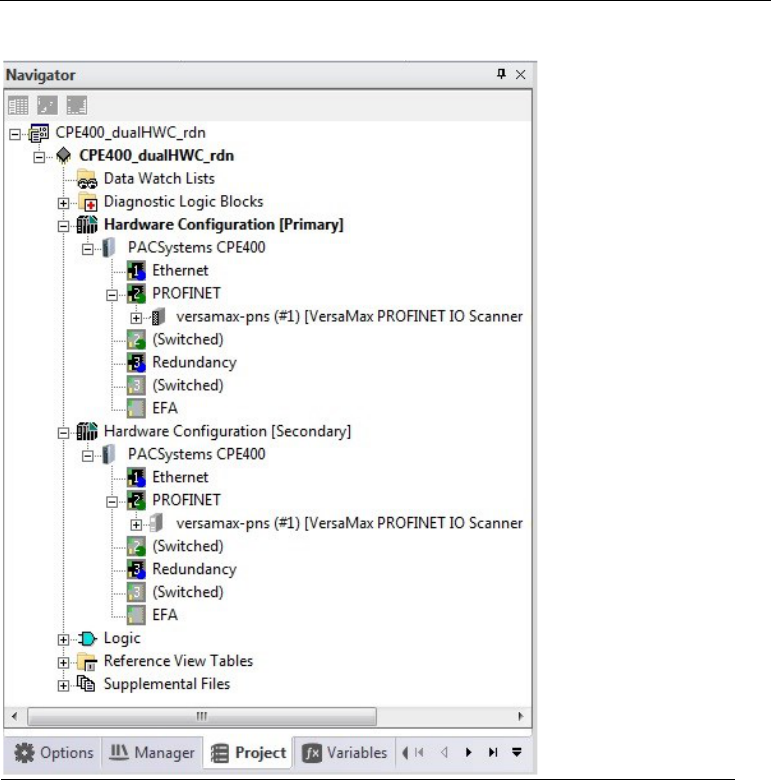

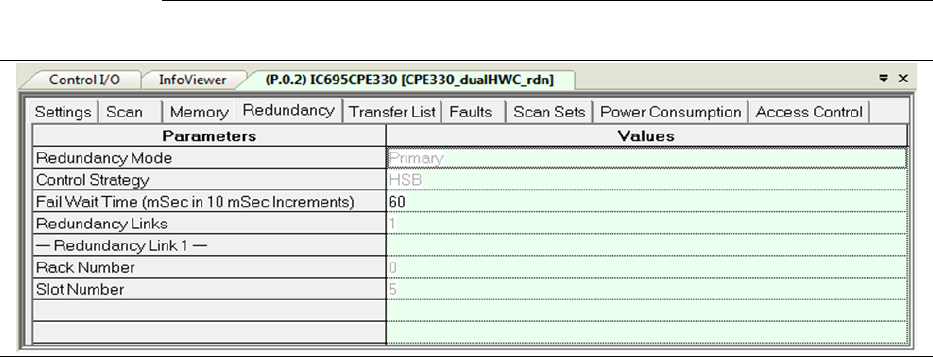

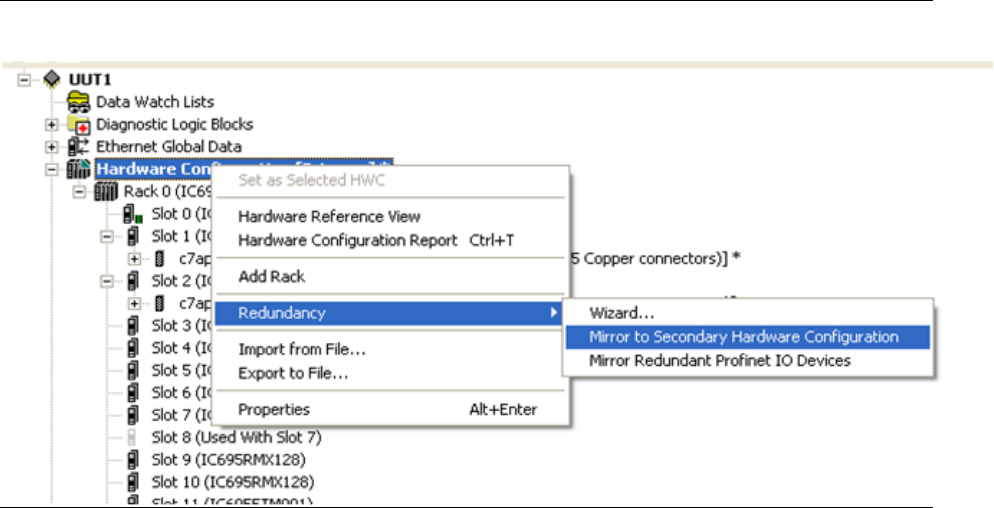

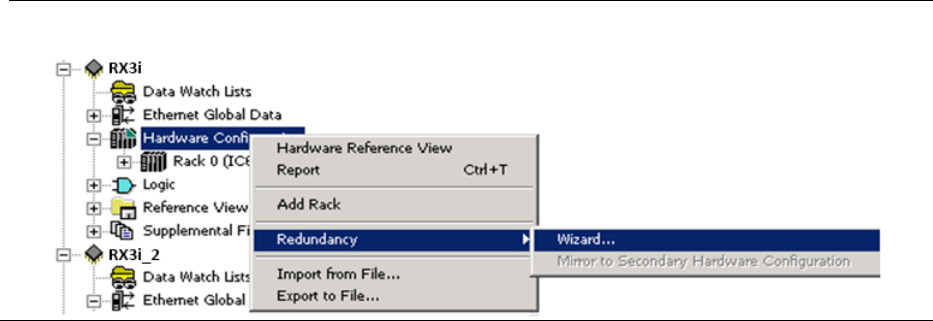

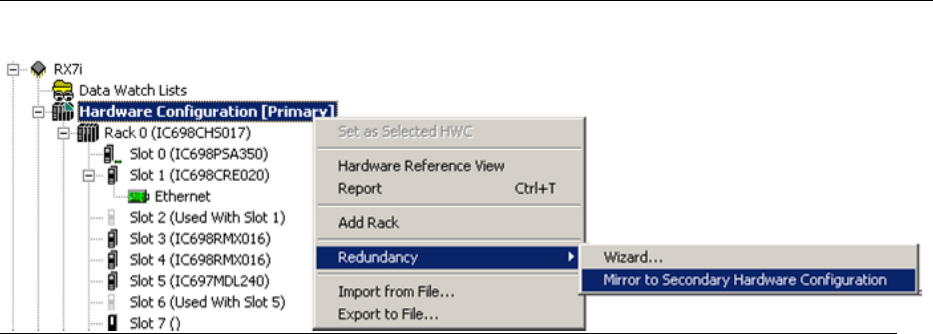

j. Now that you have finished populating the Hardware Configuration of the Primary

CPU, right-click on the ‘Hardware Configuration [Primary]’ node, select

Redundancy, and select Mirror to Secondary Hardware Configuration.

This operation will copy the ‘Hardware Configuration [Primary]’ (including the

transfer lists, the PNC, and the redundantly controlled PROFINET devices) to the

‘Hardware Configuration [Secondary]’ HWC. The result should look similar to Figure

6. (In this diagram, only one PNS is shown.)

Figure 6: RX3i Hot Standby Redundancy Quick Start with PROFINET I/O

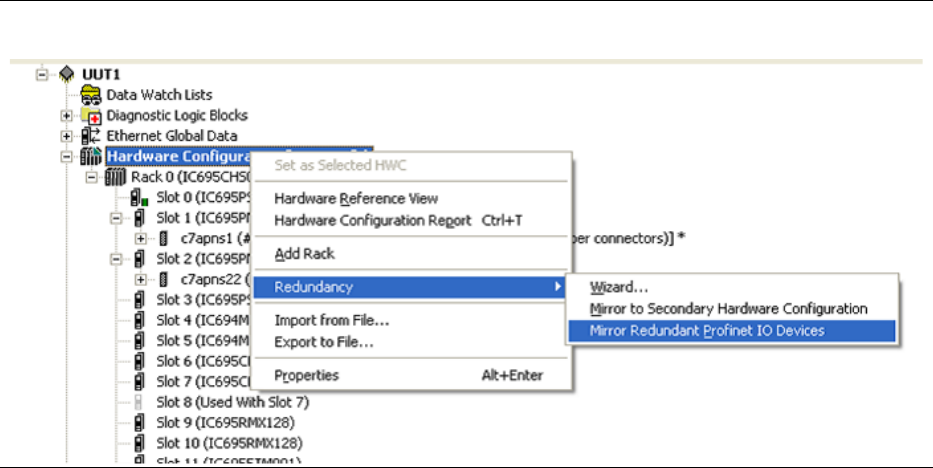

m) Select the PNC underneath the ‘Hardware Configuration [Secondary]’ HWC.

i. Assign a unique name and IP address to this PNC.

ii. Set this PNC’s Media Redundancy parameter to Client.

iii. In order to fail-over to the Backup PLC if both PNC MRP ports are disconnected,

set the ports used for MRP to Network Port # Critical = True (the 2nd MRP port will

auto-select when the first MRP port is selected).

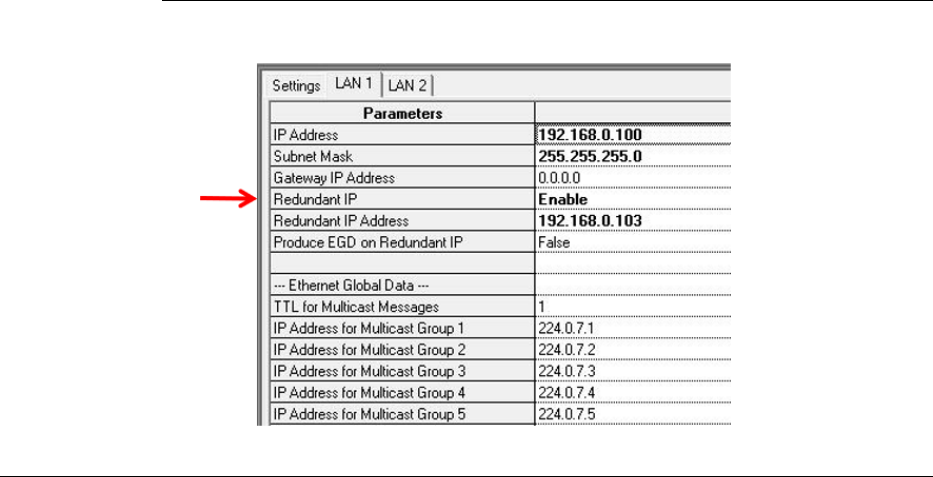

n) For each Ethernet module in the Secondary Hardware Configuration, assign a unique IP

address.

8) Add logic to the target.

Note: This is the sequence for downloading configurations into a new redundancy

system. Both units are initially stopped with no configuration.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 2

GFK-2308W May 2021

RX3i Hot Standby Redundancy Quick Start with PROFINET I/O 19

9) Download the Hardware Configuration and Logic to the Primary controller.

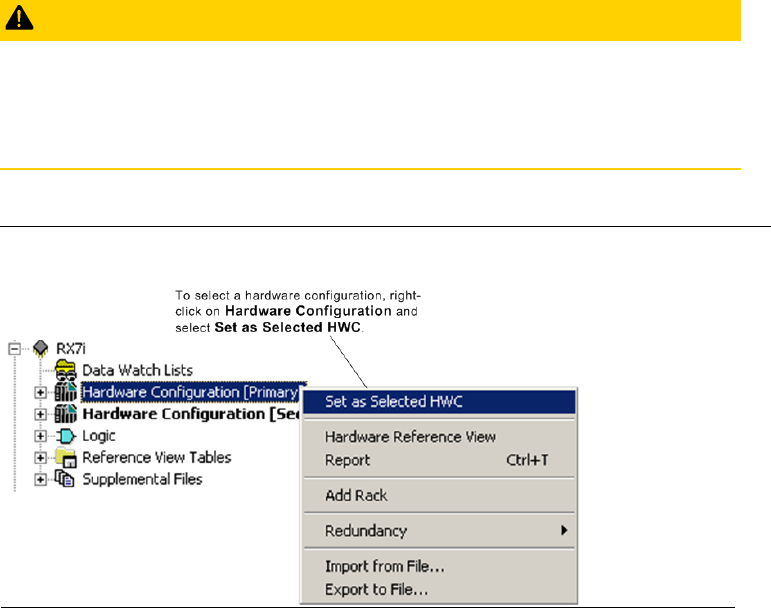

a) Right-click on the ‘Hardware Configuration [Primary]’ node and select Set as

Selected HWC. (If this menu item is greyed out, then you already have the

Primary HWC selected.)

b) Click on the target node in PME’s Navigator. In the Property Inspector, set

the Physical Port and IP Address so that they correspond to your Primary

controller.

c) Select Target -> Go Online.

d) Select Target -> Download <target name> to controller

e) Select Hardware Configuration and Logic and click OK.

i. Expect the Primary CPU to log a Redundancy link communication failure

Controller fault for each RMX module

6

. For example:

0.6

Redundancy link communication failure

0.7

Redundancy link communication failure

ii. Confirm that the Primary CPU did not record any Loss of Device faults in

its I/O fault table.

f) Select Target -> Go Offline.

10) Download the Hardware Configuration and Logic to the Secondary controller.

a. Right-click on the ‘Hardware Configuration [Secondary]’ node and select Set

as Selected HWC.

b. Click on the target node in PME’s Navigator. In the Property Inspector, set

the Physical Port and IP Address so that they correspond to your Secondary

controller.

c. Select Target -> Go Online.

d. Select Target -> Download <target name> to controller.

e. Select Hardware Configuration and Logic and click OK.

i. For both RMX modules in both units, confirm that the LINK OK LEDs

are ON. (This might take a few seconds.)

ii. Confirm that the Secondary CPU did not record any Loss of Device

faults in its I/O fault table.

6

Dual RMX configuration is no longer required for the CPE330 with PME SIM14 or later and firmware 9.75 or

later. This also applies to the CPE330 when it is in CRU320 compatibility mode,

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 2

GFK-2308W May 2021

RX3i Hot Standby Redundancy Quick Start with PROFINET I/O 20

f. Select Target -> Go Offline.

11) You may now connect the last link of the PROFINET network (left open in step 4) above)

to complete the ring.

12) Connect PME to the Primary CPU, and put the Primary CPU into Run mode.

Expect the Primary CPU to log a Primary CPU is Active; no Backup Unit available Controller

fault. For example:

0.2

Primary CPU is Active; no Backup Unit available

13) Connect PME to the Secondary CPU, and put the Secondary CPU into Run mode. Expect

the Primary CPU to log a Primary CPU is Active and Secondary CPU is Backup Controller

fault. For example:

0.2

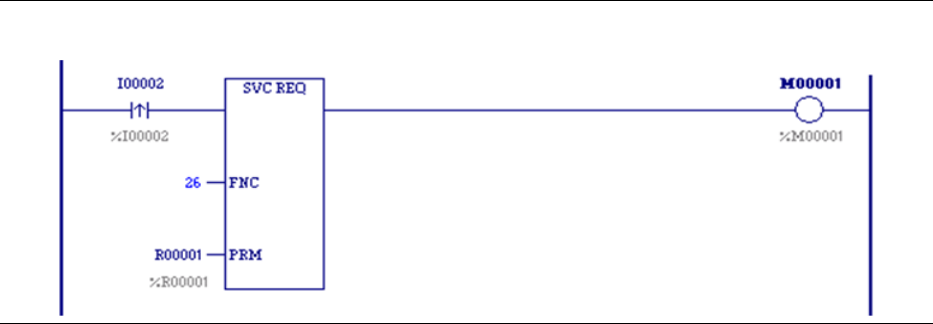

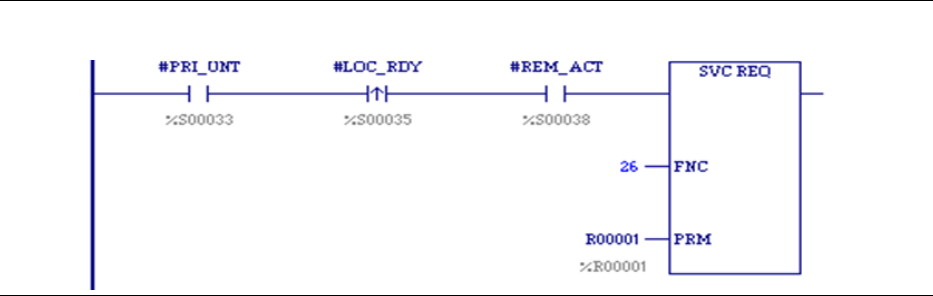

Primary CPU is Active and Secondary CPU is Backup

This quick start procedure demonstrates the setup and configuration of a basic RX3i

Hot Standby CPU Redundancy system that uses PROFINET I/O. This basic setup can

be used to learn about other Redundancy features such as Role Switching, Transfer

Lists, Non-Synchronized Active Unit (NSAU), and Redundant IP which are described in

the latter chapters of this manual.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 3

GFK-2308W May 2021

RX3i Hot Standby Redundancy Quick Start with Ethernet I/O 21

Section 3: RX3i Hot Standby Redundancy

Quick Start with Ethernet I/O

This chapter provides an overview of the steps needed to configure and operate a

basic RX3i Hot Standby (HSB) CPU Redundancy system with one Ethernet Remote I/O

(ENIU) using an ENIU Machine Edition template.

A template set is a zip file containing pre-configured Ethernet NIU (ENIU) and

controller projects for PAC Machine Edition or PAC Process Control. The template set

simplifies the configuration of the controllers and ENIUs because the Ethernet Global

Data exchanges are already set up, along with a default number of inputs and

outputs for the system. If the default values are used, the only steps needed to

implement I/O communication are assigning Ethernet IP addresses, configuring I/O

modules and storing to the controllers and ENIUs. The templates may be

downloaded from PAC Machine Edition. Refer to the PACSystems RX3i Ethernet

Network Interface Unit User’s Manual, GFK-2439.

Note: The Primary and Secondary CPUs in a redundancy system must be of the same

type. An RX3i controller cannot function as a redundant pair.

1) Set up two identical controller systems. One system will be designated as Primary and the

other will be designated as Secondary.

a. For rack-mounted systems, install one Redundant CPU, one or two RMX modules

and three Ethernet (ETM001) modules each into each system. Install the ETM

modules in the slot locations indicated by Table 3 for RX3i.

b. For CPE330, you may not replace the rack-mounted ETM modules with

embedded Ethernet: install rack-mounted ETM modules per Table 3.

c. ENIU templates for embedded PROFINET Controllers are not available at time of

publication, so this feature cannot be used with CPE400, CPL410 or with the

embedded PROFINET Controller of a CPE330 at this time.

2) (Applies to CRU320 only.) With the CPU battery disconnected, apply power to the racks.

When power is applied to the RMX module an internal loopback test occurs; the OWN

DATA and SIGNAL DETECT indicators turn on briefly during this test. When the RMX

module and the CPU are powered up and functioning properly, the RMX module’s OK

indicator is on.

3) (Applies to CRU320 only.) Connect a battery to each redundant CPU.

The redundant CPUs support Error checking and correction (ECC) memory, which must

be initialized at least one time with the battery disconnected. Once ECC memory is

initialized, the CPU can be power cycled with the battery connected.

4) Download and unzip the appropriate template set for your system.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 3

GFK-2308W May 2021

RX3i Hot Standby Redundancy Quick Start with Ethernet I/O 22

Templates for redundancy systems are available from the Support website. On the

website, select Downloads, then select the Developer Files category.

For a list of available template sets, refer to the PACSystems RX3i Ethernet Network

Interface Unit User’s Manual, GFK-2439. Each template set consists of a Controller

template and an ENIU template.

5) Using the Machine Edition Logic Developer software, restore the Controller project from

the appropriate ENIU template set.

6) Open the restored project. Assign IP addresses to all the Ethernet LANs.

In assigning IP addresses, consider the following functions:

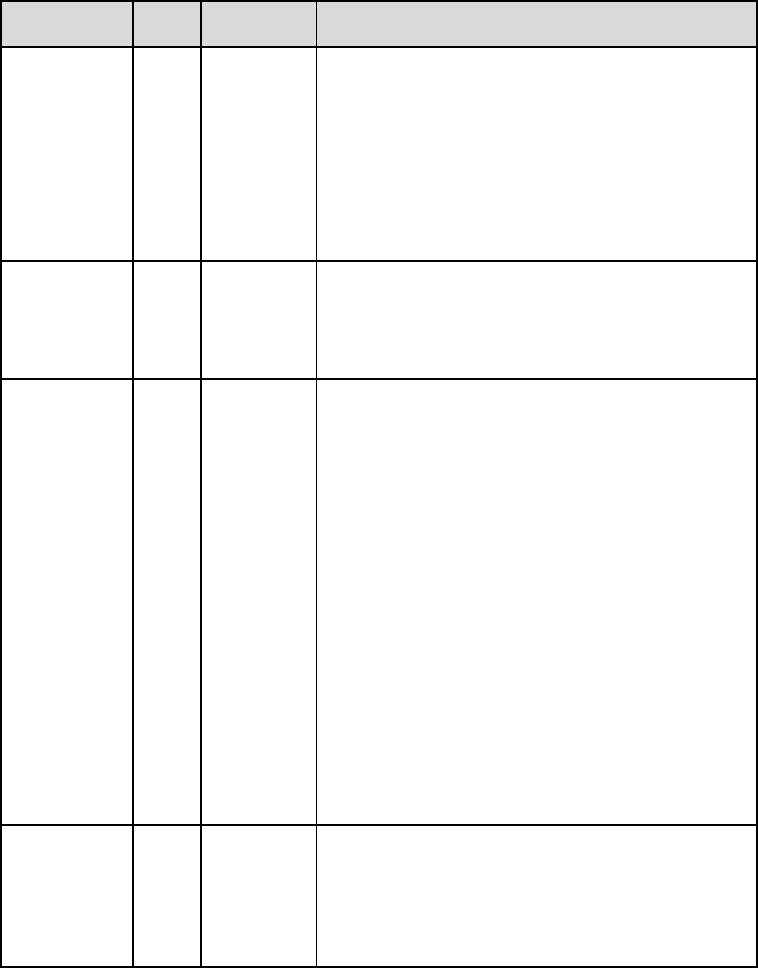

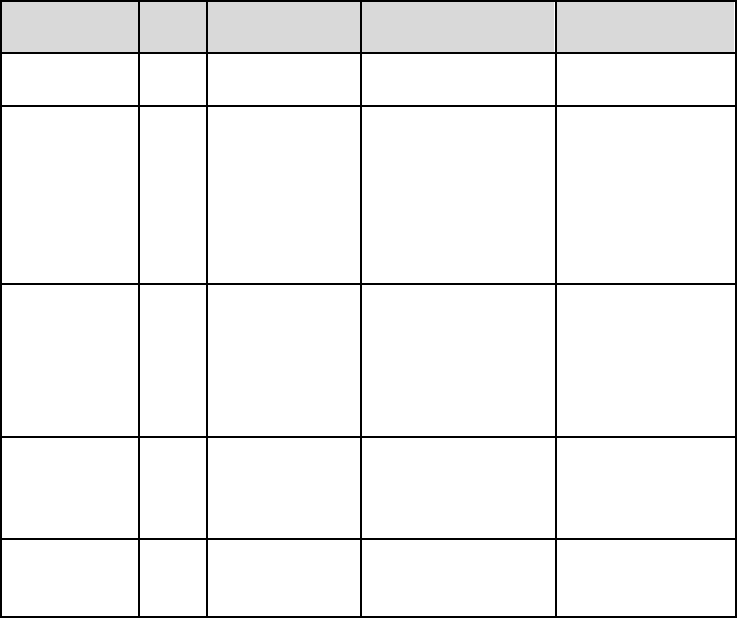

Table 3: RX3i Rack-mounted Configuration

Ethernet Interface

Function

ETM001 in Slot 6

7

Programmer connection to your computer

Requires a Redundant IP address, which should be the same IP Address

for both the Primary and Secondary rack systems.

ETM001 in Slot 7

Private network, LANA for Ethernet I/O exchanges

ETM001 in Slot 8

Private network, LANB for Ethernet I/O exchanges

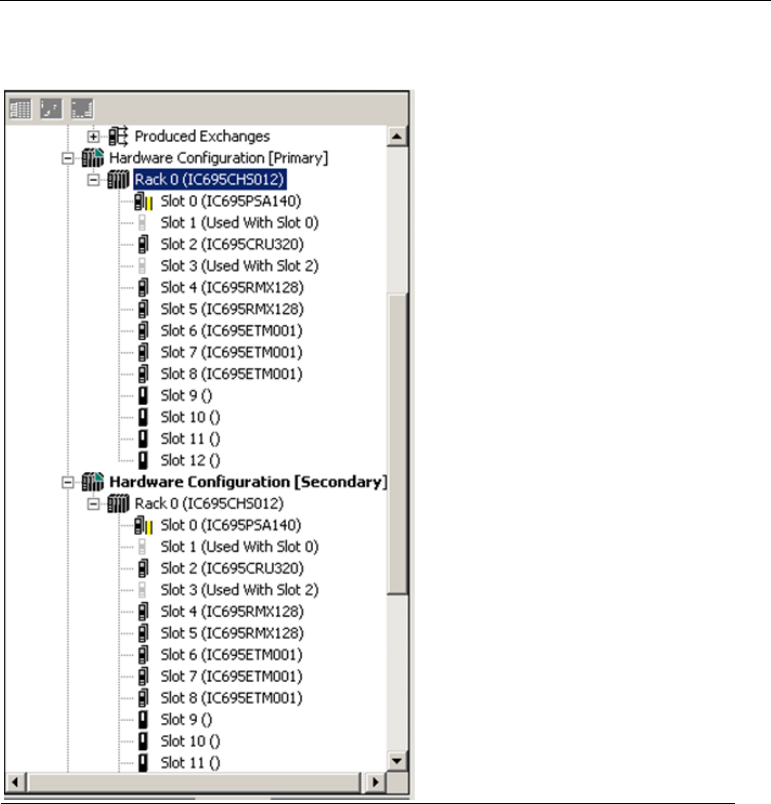

The hardware configuration should appear similar to Figure 7, which shows an RX3i

configuration:

7

ETM001 in Slot 6 may be replaced by the Ethernet port embedded in CPUs such as CPE330.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 3

GFK-2308W May 2021

RX3i Hot Standby Redundancy Quick Start with Ethernet I/O 23

Figure 7: RX3i Hardware Configuration Provided by an ENIU Controller Template

Project

7) Use fiber-optic cable to connect each RMX module in the Primary Rack to the

corresponding RMX module in the Secondary Rack (the module in the same Slot

number) as described in Figure 8.

Using an LC-compatible fiber-optic cable, connect the TX connector on one RMX module to the

RX connector of the other RMX module, and vice-versa (refer to Figure 8.) When the fiber-optic

transceiver detects a signal on the network, the SIGNAL DETECT indicator will be on.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 3

GFK-2308W May 2021

RX3i Hot Standby Redundancy Quick Start with Ethernet I/O 24

Figure 8: Fiber Optic Cable Connections for RMX Modules

Note: Ensure that the cable type matches the module type, such that, single-mode cable is

used for single mode modules and multimode cable is used for multimode modules.

8) In PAC Machine Edition, close the Controller project and restore the ENIU project from an

ENIU template set:

Open the project and on target ENIU_01 open the Hardware Configuration. Set the IP

addresses of the ETM001 modules, taking into consideration that the ETM001 in Slot 4

of the ENIU rack will be on a private network called LANA (connected to LANA of the

Redundancy CPUs) and the ETM001 in Slot 5 will be on a private network called LANB

(connected to LANB of the Redundant CPUs).

The hardware configuration should appear similar to Figure 9, which shows an RX3i

configuration.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 3

GFK-2308W May 2021

RX3i Hot Standby Redundancy Quick Start with Ethernet I/O 25

Figure 9: ENIU Hardware Configuration Provided by an ENIU Template Project

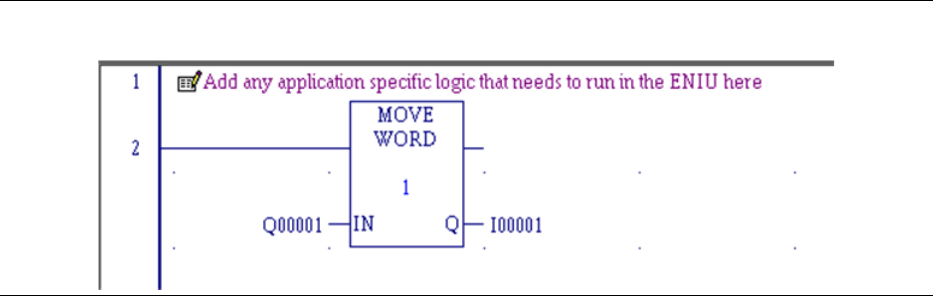

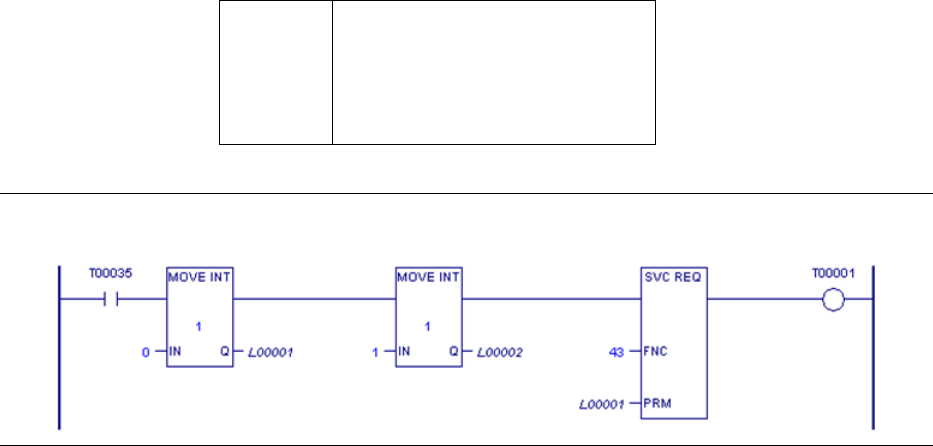

9) Add I/O loopback logic to confirm data transfer between ENIU and Redundant CPUs

Under the Logic node in PAC Machine Edition, open the Program Block

Local_User_Logic. Add the logic shown in Figure 10 to loop outputs %Q1-%Q16 back

to inputs %I1-%I16.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 3

GFK-2308W May 2021

RX3i Hot Standby Redundancy Quick Start with Ethernet I/O 26

Figure 10: Add Ladder Logic for ENIU

10) (Applies to rack-mounted systems only.) Install a Power supply, RX3i ENIU

(IC695NIU001) and two ETM001 modules into an RX3i backplane as shown the

hardware configuration in step 6). Apply power to the system.

11) Connect your PC to the ENIU via a Serial cable from the ENIU module’s COM1 or

COM2 port to one of your PC’s COM ports or install an additional ETM001 module to

the ENIU rack to provide connectivity via Ethernet. With the template folder open in

PAC Machine Edition, connect to the ENIU either by a COM port or by Ethernet.

Store the ENIU_01 application to the ENIU and put the ENIU into run mode.

12) Connect Ethernet cables between the Redundant CPUs and the ENIU rack system.

RX3i Connections

LANA: Connect one Ethernet cable from ETM001 in Primary Rack Slot 7 to

ETM001 in ENIU Rack Slot 4. Connect one Ethernet cable from ETM001 in Primary

Rack Slot 8 to ETM001 in ENIU Rack Slot 5.

LANB: Connect one Ethernet cable from ETM001 in Secondary Rack Slot 7 to

ETM001 in ENIU Rack Slot 4. Connect one Ethernet cable from ETM001 in

Secondary Rack Slot 8 to ETM001 in ENIU Rack Slot 5.

13) Connect Ethernet cables between an Ethernet switch connected to your PC and the

ETM001 modules assigned as Programmer connections in both the Primary and

Secondary CPU systems.

14) Close _10ENIU_CRU_DLDI_ENIU_1_10 project in PAC Machine Edition and again open

project _10ENIU_CRU_DLDI_Controller

a) Right-click on the Primary Hardware Configuration node and select Set as

Selected HWC. Connect to the Secondary CPU, store the application and put the

CPU in run mode.

b) Disconnect from the Primary CPU. Right-click on the Secondary Hardware

Configuration node and select Set as Selected HWC. Connect to the Secondary

CPU, store the application and put the CPU in run mode.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 3

GFK-2308W May 2021

RX3i Hot Standby Redundancy Quick Start with Ethernet I/O 27

c) Right-click on the Reference View Tables node and select New. Double-click the

RefViewTable10 node just created. In the address box, enter %Q1. In the next

address box below %Q00001, enter %l1. Right-click in the Values area just to the

left of the Address boxes and select Format View Table. Check the box labeled

Apply to Whole Table, select Word for the Display Type, select Hex for the Display

Format and click Ok. Enter values into the %Q00001 values area and notice that

the same values are displayed at %l00001 because of the loopback logic in the

ENIU.

NOTE: For details on configuring an RX3i Genius dual bus redundancy system,

refer to Appendix A.

This quick start guide procedure demonstrates setup of a PACSystems

Redundancy Controller pair controlling one ENIU remote IO station. This basic

setup can be used to learn about other CPE Redundancy features such as Role

Switching, Transfer Lists Non-Synchronized Active Unit (NSAU) and Redundant

IP. For details on the operation of CPU Redundancy systems, refer to the other

chapters in this manual.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 4

GFK-2308W May 2021

System Configuration 28

Section 4: System Configuration

This chapter describes the hardware components for a Hot Standby CPU Redundancy

system and describes system configurations for the basic redundancy schemes

supported by PACSystems controllers.

For installation instructions, refer to

• PACSystems RX3i System Manual, GFK-2314.

4.1 Components of a Hot Standby Redundancy

System

• Core Systems

• Redundant CPU

• Redundancy Memory Xchange modules

• Redundant I/O Systems

4.1.1 Core Systems

RX3i Systems with Racks

In an RX3i redundancy system where the CPU is mounted in an RX3i rack, an RX3i

(IC695CHS0xx) Universal Backplane must be used as the CPU rack. This rack is

referred to as Rack 0. For specific backplane versions required, refer to the Important

Product Information document provided with your RX3i CPU.

Any RX3i expansion rack or any Series 90-30 expansion rack that is supported by RX3i

can be used in a rack-mounted RX3i redundancy system.

RX3i Systems without Racks

CPE400 and CPL410 are RX3i CPUs which cannot be installed in an RX3i rack. They

therefore do not support RMX modules, rack-mounted PNC modules or rack-

mounted Ethernet modules. Sections of this manual will therefore specify how

CPE400/CPL410 systems may be used in Redundancy applications. While the system

rack is physically absent in CPE400/CPL410 configurations, the CPE400/CPL410 itself

is able to provide all the equivalent functionality via its embedded PROFINET

controller and embedded Ethernet networks. All I/O in this type of system is

PROFINET I/O, since no rack-mounted I/O is permitted.

CPE400/CPL410 do not support Hot Standby Redundancy for Ethernet IO. Such

systems require an ETM001, which the CPE400/CPL410 do not support.

CPE400/CPL410 do not support expansion racks.

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 4

GFK-2308W May 2021

System Configuration 29

4.1.2 Redundant CPU Modules

To use the features described in this manual, RX3i Redundant CPUs (except CPE400

and CPL410, which are not rack-mounted CPUs) must be installed in any slot in rack

0.

Note: A given feature may not be implemented on all PACSystems CPUs. To

determine whether a feature is available on a given CPU model and firmware version,

please refer to the Important Product Information (IPI) document provided with the

CPU.

The CPU provides configurable reference memory limits for %AI (Analog Input), %AQ

(Analog Output), %R (Register), and %W (bulk memory area) reference memory, as

well as symbolic discrete reference memory and symbolic non-discrete reference

memory. For additional CPU features and performance specifications, refer to the

PACSystems RX3i and RSTi-EP CPU Reference Manual, GFK-2222.

Operation of the CPUs can be controlled by the three-position RUN/STOP switch or

remotely by an attached programmer and programming software. Program and

configuration data can be locked through software passwords. The LEDs on the front

of the module indicate CPU and Ethernet interface status.

• Redundant IP address

• Production of selected EGD exchanges in Backup mode

• Up to 255 Ethernet Global Data (EGD) exchanges with up to 100 variables

per exchange.

• EGD upload and selective consumption of EGD exchanges.

• Upload and download of an Advanced User Parameter (AUP) file, which

contains user customizations to internal Ethernet operating parameters.

• Run mode store of EGD (PACSystems releases 5.5 and later), which allows

you to add, delete or modify EGD exchanges without stopping the controller.

For details on using this feature, refer to the PACSystems RX3i and RSTi-EP

TCP/IP Ethernet Communications User Manual, GFK-2224.

• Redundant CPUs Compared to Standard PACSystems CPUs

• The following features are not available:

• I/O and module interrupts: This includes the single edge triggered interrupts

from the discrete input modules, the high alarm and low alarm interrupts

from the analog input modules, and interrupts from VME modules. A

program that declares I/O Interrupt triggers cannot be stored to a

Redundant CPU.

• Interrupt Blocks (I/O, timed, module): Logic that contains interrupt blocks

cannot be stored to a Redundant CPU.

• Stop I/O Scan mode: If an attempt is made to place a Redundant CPU in this

mode, the controller will reject the selection and return an error.

• #OVR_PRE %S reference, which indicates whether one or more overrides are

active, is not supported in a Redundant CPU, and should not be used.

• RX3i Redundant CPUs do not support the PACMotion module

(IC695PMM335).

PACSystems™ RX3i Hot Standby CPU Redundancy User Manual Section 4

GFK-2308W May 2021

System Configuration 30

• The following features operate differently in redundant CPUs than they do in

standard PACSystems CPUs:

• Error checking and correction (ECC) is enabled.

8

• RUN/DISABLED mode. This is explained in Section 6:, Operation.

• User-configurable fault actions are not used when the CPUs are

synchronized.

• STOP to RUN mode transition. For details, refer to Section 6.2, Synchronizing

Redundant CPUs.

• Background Window Timer (in Normal Sweep mode) default is 5ms. It is

highly recommended that the Background Window Timer be set to the same

value for both CPUs making up a redundancy pair.

• By default, Ethernet Global Data (EGD) is produced only by the Active unit.

The Backup unit can produce individual EGD exchanges that are configured

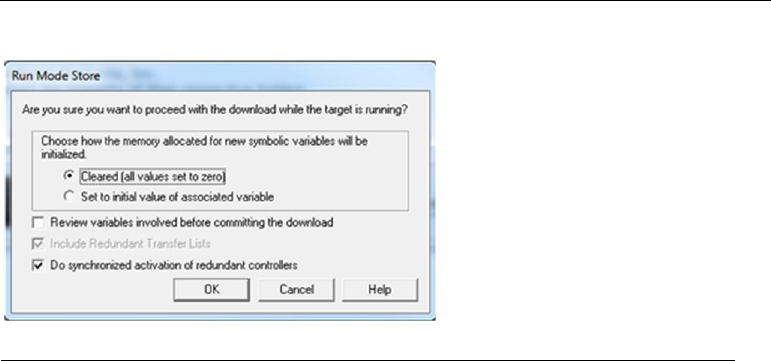

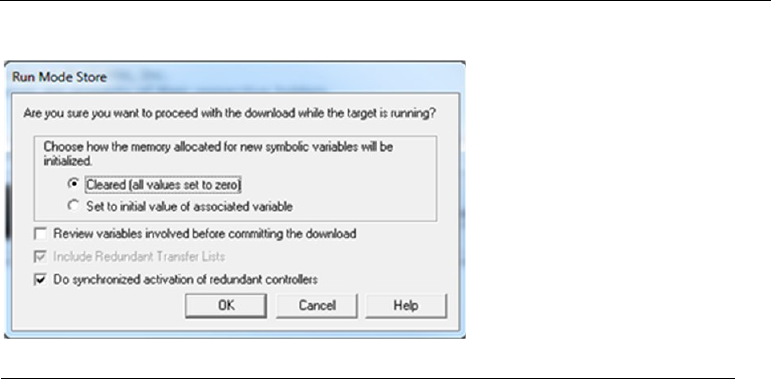

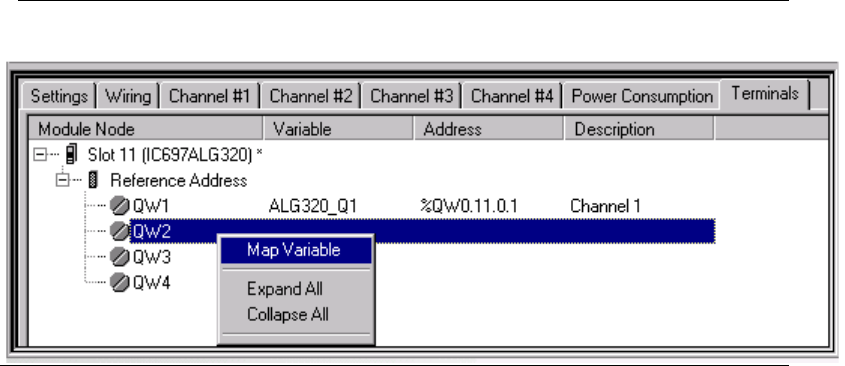

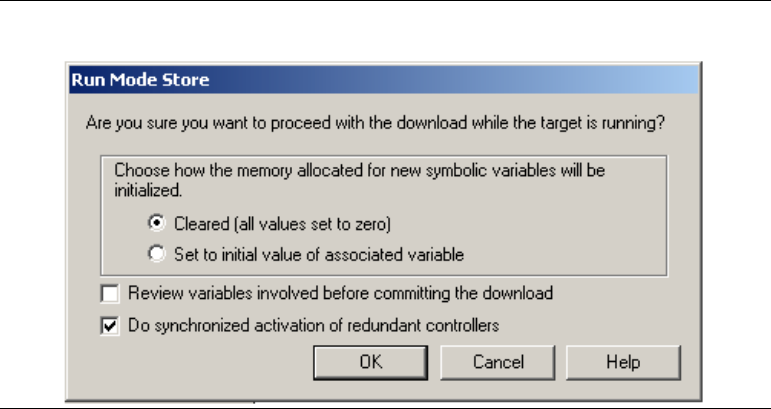

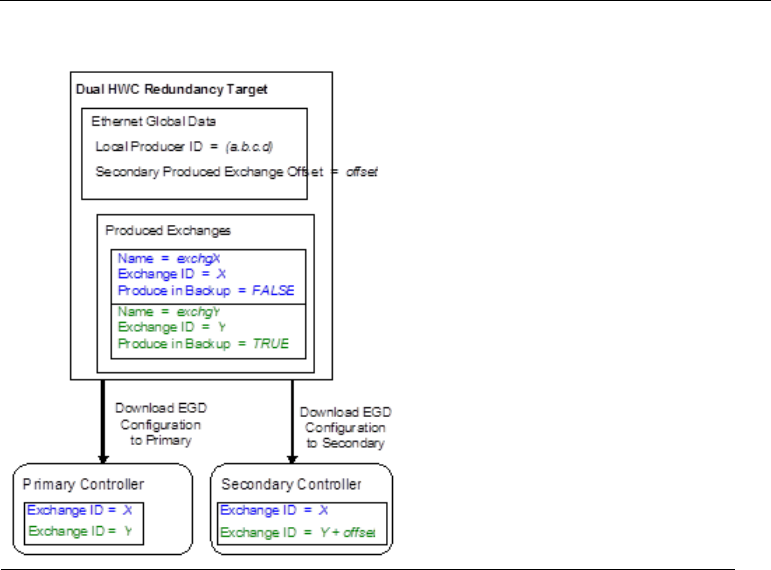

for production in Backup mode.